Are you a Small specialty coffee roaster? Have you ever considered entering the single-serve coffee market for a higher profit margin, but faced challenges in sourcing? or maybe you are in the coffee pod co-packing business and thinking about manufacturing the empty K-Cup in-house?

If you ever searched how to manufacture private label K-cup coffee pods, an issue often encountered when you search relative topics on search engines and B2B websites is what is a “true” K-Cup manufacturing machine. Is the machine that fills and seals ground coffee into pre-fabricated K-Cups versus the machine that manufactures the K-Cups?

The purpose of this guide is to investigate the capabilities of a true “K-Cup Manufacturing Machine”, which is instrumental in the production of conventional K-Cup coffee pods and compostable coffee pods.

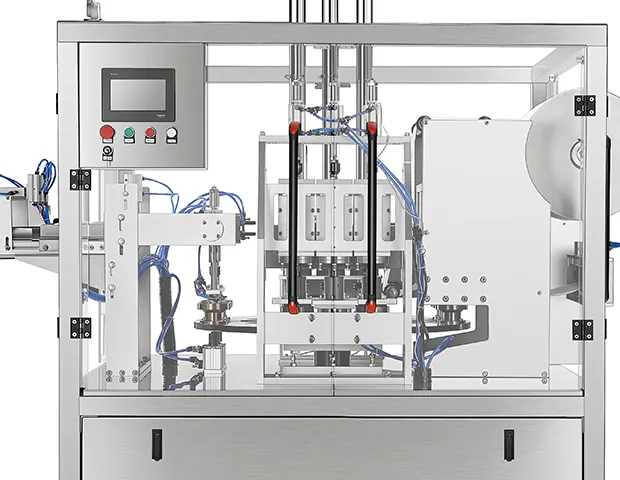

K-Cup Manufacturing Machine

The K-Cup manufacturing machine is able to weld filters directly onto plastic, biodegradable, and compostable coffee pods, making this versatile machine indispensable to any coffee pod producer looking for diversification or switching to more sustainable options in their product lineup or transition to more sustainable options!

The Working Processes of K-Cup Manufacturing Machine

Loading the Filter Roll Film: The roll film, deciding the final brewing performance, would be automatically loaded and extended.

Cutting Roll Film into Round Filters: Once loaded, the K-cup manufacturing machine precisely cuts the continuous roll of film into individual round filter shapes. This cutting process requires high accuracy since each filter’s diameter should be exactly 98.5mm.

Placing the Empty Cup into the Mold: Simultaneously, the empty K-Cups are precisely placed into the K-Cup manufacturing machine’s designated molds.

Welding the filter into the coffee pod: The K-Cup manufacturing machine develops exclusive technology to connect filters with coffee pods tightly. Through smart adjustments, the K-Cup manufacturing machine could also be applied to weld pre-cut filters onto compostable coffee pods.

Compostable K-Cup Coffee Pods Manufacturing

The K-Cup manufacturing machine is capable of welding filters into “compostable K-Cup coffee pods”, which offers a new business market to small-batch coffee roasters and coffee pods co-packing factories.

For small specialty coffee roasters, the K-Cup manufacturing machine provides a new business growth opportunity focused on sustainability. The widely used plastic K-Cups are often criticized due to the negative effects on the environment. By producing “non-plastic K-Cups” and “compostable K-Cups”, businesses can contribute to sustainable development, enhance brand image, and appeal to a broader customer base.

Unlike other “k-cup manufacturing machines” that may be unstable with handling compostable materials, this machine is designed to weld filter onto compostable coffee pods with the same precision and speed as conventional materials. For coffee pod co-packing factories, the versatility could offer a wider range of K-Cup manufacturing services to their clients, catering to the growing demand for sustainable solutions.

What is Compostable Packaging Material?

“Compostable packaging” refers to materials that break down into their natural elements during composting processes without leaving toxic residues behind, leaving no toxic lingerings behind. For compostable coffee pods, this usually means plant-based bioplastics or other biodegradable materials that break down completely within days after use.

“What is Home Compostable?”

Home compostable materials generally could break down in a backyard compost pile, where conditions are less controlled and temperatures are lower than in industrial facilities.

If you choose to produce home-compostable K-Cup coffee pods, you would spot a niche in the market without serious competition. It directly targets people who want to easily get rid of their coffee pods at home, providing the utmost ease and a strong “green” message. This can make environmentally aware customers very loyal to your brand.

“What Is Industrial Compostable?”

Industrial compostable materials require the specific, controlled conditions found in industrial composting facilities, like higher temperatures, controlled moisture levels, and specialized microbial activity.

Choosing an industrial compostable coffee pod packaging means that the co-packing company and coffee roasters would have a broader selection of raw materials.

Why Choose SANEU?

For small specialty coffee roasters and coffee pods co-packing factories, investing in a SANEU “K-Cup manufacturing machine“:

- Quality and Durability: Built with food-grade 304 stainless steel and equipped with high-quality components, the machine is designed for durability and reliability.

- Precision and Efficiency: The advanced welding technology ensures perfect integration of the filter and cup, while the high capacity of 50-60 capsules per minute guarantees efficient production.

- Seamless Integration: Designed for integration with existing packaging systems, minimizing disruptions to your production line.

- User-Friendly Operation: The Siemens touchscreen and Schneider programmable control system simplify operating procedures, reducing training time.

- Sustainable Future: Our k-cup manufacturing machine’s capability to handle “compostable cups” would benefit your business to meet the growing demand for “non-plastic K-Cups” and “compostable coffee pods for Keurig”.