In the high-stakes world of coffee packaging, a single millimeter in bean size variance can mean the difference between smooth operations and costly production delays. As a packaging specialist who’s optimized countless coffee production lines, I’ve witnessed the evolution of Vertical Form Fill Seal (VFFS) technology from basic bagging systems to sophisticated platforms that can handle everything from fine espresso to jumbo peaberry beans.

The challenge isn’t just finding a machine that works today – it’s selecting a system that will adapt to your growing operation while maintaining precision and speed. With coffee packaging technology advancing at an unprecedented pace, understanding the key factors that influence VFFS performance has never been more crucial for roasters looking to scale their operations.

Machine Compatibility with Coffee Bean Size

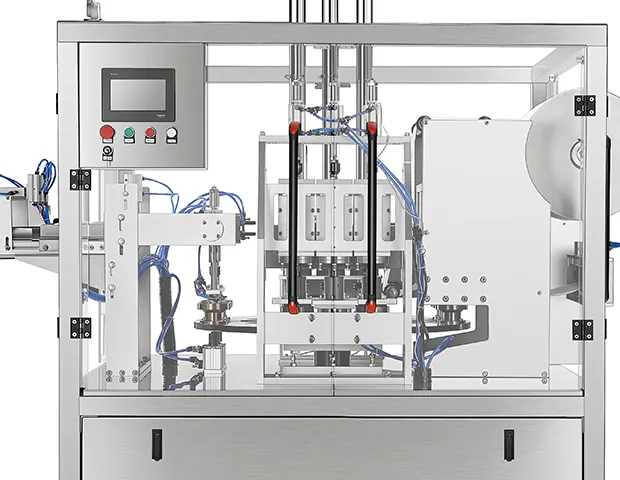

When selecting a VFFS packaging system for coffee operations, the machine’s ability to handle diverse bean sizes and types is paramount. Whole bean coffee, with its dense and consistent nature, typically flows smoothly through high-speed packaging operations, making it an ideal candidate for automated systems. However, the real challenge lies in finding equipment that can seamlessly transition between different products.

Modern VFFS machines excel in their versatility, offering adjustable features that accommodate everything from fine-ground espresso to large whole beans. Stand-up pouches and flat pouches require different handling parameters, and the most effective machines can switch between these formats without compromising efficiency.

I’ve found that compatibility issues often surface when machines aren’t properly configured for specific bean characteristics. Weight distribution and bean shape can significantly impact packaging accuracy. The solution lies in selecting equipment with customizable settings that can be fine-tuned to your product range. For instance, adjustable funnels and precise dosing mechanisms ensure consistent filling regardless of bean size variations, preventing product damage and maintaining packaging integrity.

Efficiency and Speed

In the fast-paced coffee industry, production speed can make or break your operation. High-speed VFFS machines have revolutionized large-scale roasteries, enabling continuous production runs while minimizing costly downtimes. I’ve observed that ceramic packaging components particularly excel in maintaining rapid filling and sealing processes without compromising quality.

The latest VFFS systems can achieve impressive throughput rates, making them ideal for operations handling substantial volume. However, raw speed isn’t everything – precision matters just as much. Modern machines incorporate sophisticated weighing and dosing systems that ensure each package contains exactly the specified amount of coffee, even at high velocities.

From my experience working with various coffee packaging operations, the sweet spot lies in finding equipment that balances velocity with accuracy. For instance, integrated check-weighing systems can automatically adjust filling parameters in real-time, maintaining consistent package weights even during high-speed runs. This dual focus on speed and precision not only optimizes production efficiency but also ensures product quality meets exacting standards, ultimately driving better bottom-line results.

Ease of Maintenance

Maintaining VFFS machines efficiently can significantly impact your coffee packaging operation’s productivity. I’ve found that complex machine designs often create accessibility challenges, particularly when it comes to reaching internal components for cleaning and maintenance. The key is to look for machines with streamlined, intuitive designs that simplify these essential tasks.

Modern VFFS systems with modular architectures offer distinct advantages in maintenance efficiency. When individual components can be quickly removed and serviced, you’ll spend less time troubleshooting and more time producing. I particularly recommend focusing on machines with easily accessible sealing jaws and filling systems, as these areas typically require the most frequent attention.

The industry has evolved toward maintenance-friendly designs, with suppliers like Syntegon leading the way. Their preventative maintenance programs and on-site support services complement machines engineered for easy upkeep. In my experience, investing in equipment with clear maintenance protocols and readily available technical support can dramatically reduce downtime and extend machine life. This approach not only preserves operational efficiency but also protects your investment over the long term.

Packaging Technology Used

The choice of filling technology can dramatically impact your coffee packaging operation’s success. Auger fillers excel in handling ground coffee, delivering precise portions with remarkable consistency. Having worked extensively with various systems, I’ve found that volumetric filling methods work better for whole beans, offering superior control over product flow and reduced breakage.

The technology driving modern VFFS machines has evolved significantly, particularly in terms of precision control. Advanced weighing systems now integrate seamlessly with filling mechanisms, ensuring exact dosing while maintaining high throughput rates. These systems constantly monitor and adjust parameters in real-time, virtually eliminating under or overfilling issues.

Recent innovations have transformed how we approach coffee packaging. The integration of degassing valves directly into the packaging process has streamlined production while ensuring product freshness. Suppliers now offer machines capable of handling recyclable materials and incorporating eco-friendly components without sacrificing performance. From my experience, these technological advances not only enhance product safety but also contribute significantly to shelf life extension, making them invaluable for modern coffee packaging operations.

Cost-Effectiveness

When evaluating VFFS machines for coffee packaging, I’ve found that focusing solely on initial purchase costs can be misleading. While high-speed VFFS systems require substantial upfront investment, they typically deliver significant returns through increased production efficiency and reduced labor requirements. The key is analyzing total cost of ownership over the machine’s lifecycle.

I’ve witnessed numerous coffee roasters achieve remarkable cost savings after transitioning to automated VFFS systems. One particularly striking example involved a mid-sized roastery that upgraded from manual packaging to a Premade Pouch machine. Despite the initial investment, they recovered costs within 18 months through labor savings and increased production capacity.

Modern VFFS machines excel in optimizing fill accuracy and minimizing material waste. Through precise dosing mechanisms and advanced control systems, these machines can reduce product giveaway by up to 30% compared to older systems. I’ve found that investing in machines with integrated check-weighing capabilities and automatic adjustment features pays dividends through reduced waste and improved consistency. The most effective systems combine high-speed operation with precise portion control, ensuring every package meets weight specifications while maintaining optimal production rates.

Customization Options

Modular machine designs represent a significant advancement in VFFS technology for coffee packaging. Based on my experience with systems like Syntegon’s PMX platform, these configurable modules allow operators to adapt quickly to changing production needs. I’ve seen roasters dramatically reduce changeover times and increase productivity by simply swapping out specific modules rather than reconfiguring entire machines.

The versatility of modern VFFS systems extends to bag style customization, a crucial feature in today’s competitive market. From stand-up pouches with premium finishes to flat pouches for wholesale distribution, these machines can seamlessly switch between formats. I’ve found that the ability to adjust parameters like seal strength, fill rates, and valve placement gives roasters unprecedented control over their packaging presentation.

Bespoke demands in coffee packaging have driven manufacturers to develop increasingly flexible systems. Whether it’s incorporating special degassing valves, implementing unique closure systems, or accommodating distinctive package shapes, today’s VFFS machines offer remarkable adaptability. This customization capability ensures roasters can maintain brand identity while optimizing their packaging process for efficiency and product protection.

Energy Consumption and Environmental Impact

Modern VFFS machines have transformed how we approach energy efficiency in coffee packaging operations. I’ve observed that the latest systems can reduce power consumption by up to 30% compared to older models, significantly lowering operational costs while minimizing environmental impact. These improvements come from advanced motor technologies and optimized heating systems for sealing operations.

Today’s eco-conscious packaging solutions extend beyond mere energy savings. I’ve worked extensively with machines designed to process recyclable materials like mono-PE and mono-PP, which represent the future of sustainable coffee packaging. The integration of recyclable degassing valves further enhances environmental credentials without compromising product freshness or packaging integrity.

What impresses me most is how suppliers have embraced sustainability across their entire product range. From machines that minimize material waste through precise cutting systems to those incorporating energy-recovery technologies, the focus on environmental responsibility is comprehensive. These innovations not only align with growing consumer demand for sustainable packaging but also deliver tangible cost benefits through reduced energy consumption and material optimization.

In Conclusion

Selecting the right VFFS system for coffee packaging requires a delicate balance of technical specifications, operational requirements, and future-focused planning. From machine compatibility with various bean sizes to energy efficiency considerations, each factor plays a crucial role in determining the success of your packaging operation. The investment in modern VFFS technology isn’t just about meeting today’s production needs – it’s about positioning your business for sustainable growth.

As coffee packaging continues to evolve, the most successful roasters will be those who choose systems that offer flexibility, efficiency, and environmental responsibility. By carefully evaluating these seven critical factors, you’ll be better equipped to select a VFFS solution that not only meets your immediate packaging needs but also supports your long-term business objectives.