Many small-batch specialty coffee roasters are skilled and knowledgeable in the art of roasting coffee. But how about packaging or marketing? Do you ever think about how many consumers decide to try a new coffee brand due to its appealing package? Have you ever investigated how many coffee packaging formats avaliable on the market? Did you conduct costs and returns analysis on your coffee packaging before adopting it?

Based on Businessdasher’s data, 81% of consumers bought a new product since its packaging attracted them. Over 70% of consumers said that packaging design could decide their purchase decisions, and 52% of consumers switched to a new brand due to the package. As for businesses, they also argued that they experienced a 30% profit increase after investing in product packaging. Besides, I noticed that the market research report also addressed the trends of sustainable coffee packaging and the major consumer group, generation Z, in today’s coffee market.

Drawing from my experience in the packaging industry and market analysis, I’ve compiled 10 helpful tips for specialty coffee packaging. Let’s see if these tips resonate with you!

Freshness and Aroma

When we search “what is the differences between supermarket commercial coffee and specialty coffee” online, the answers usually are quality, sourcing, aroma, freshness, and unique flavor.

The coffee’s freshness and aroma don’t only mean whether green coffee beans were fresh before sourcing or roasting. It’s also important to consider whether your coffee is fresh when consumers open the packaging.

First, always the first, you should design the coffee packaging to maximizely restore the flavor and aroma as just roasted.

The most important factors affecting coffee’s freshness are temperature, time, oxygen, humidity and light.

- Oxygen: causing staling reactions with coffee, therefore, unpleasant and rancid

- Temperature: as the temperature increases, the chemical reactions get active.

- Humidity: the risks of mold and mildew

- Light: leading to the photodegradation

- Space: more space left, more aroma would lose

Clear Information

People might make a purchase decision within a few seconds when they shop around the grocery store or on e-commerce platforms like Amazon. How could you tell potential consumers that your coffee products are distinguishable from established brands within a few seconds or make your coffee packaging stand out shelf?

Beyond the legal requirements on labeling, such as net weight, date of production/roasted, best-before date, or business address, what else should a small-batch coffee roaster tell consumers from coffee packaging?

- Roasted Level: give consumers a clear guide

- Single-origin: for consumers who pursue consistent flavor

- Blend: for consumers who prefer to try novelty and balanced coffee

- Fair Trade: 78% of consumers trust the Fair Trade Certified label products. Core Fair Trade Certificate consumers are less sensitive to price and more loyal to the brand.

- Organic Certification: The organic coffee market in North America tends to grow at a CAGR of 8.6% from 2024 to 2030.

Sustainability

As the global economy and average education level increase, more consumers realize the importance of business ethics and the negative effects produced by large commercial consumption. The sustainability in the coffee industry is not only sustainable coffee packaging, but also the sustainability in the sourcing of coffee.

For specialty coffee roasters, you could choose sustainable coffee packaging materials to avoid large amounts of waste ending up in landfills. Here is our comprehensive guide about sustainable coffee packaging. read more.

Besides, we also suggest you consider adopting sustainability from the origin since….

- Coffee is one of the most traded agricultural commodities, with a retail market value of USD 83 billion in 2022 and providing jobs for 125 million people, mostly smallholder farmers in developing countries.

- Unsustainable farming practices contribute to deforestation, habitat destruction, and soil degradation.

- A vast majority of coffee is produced by smallholder farmers who are highly dependent on coffee income, making them particularly vulnerable to market fluctuations and climate impacts.

- Coffee processing is water-intensive, and wastewater can contaminate rivers and streams, posing environmental and health risks.

- Moving towards more sustainable consumption and production requires significant investment and coordinated action among all value chain actors (buyers, standards bodies, roasters)

Convenience

Are you roasting and selling bulk coffee beans or ground coffee? Or are you trying to target younger consumers by releasing single-serve portion coffee like coffee pods, small pouch drip coffee, or freeze-dried instant coffee?

For bulk coffee, we recommend you consider pouches, bags, and cans with resealability. If your main consumer groups are younger generations, you might consider designing private label coffee pods or drip coffee bags.

Appealing Package Design

As previously mentioned, over half of consumers choose products based on attractive packaging. With Generation Z being a significant consumer group, it’s essential to design packaging that appeals to their preferences. This generation, raised in the age of social media, values packaging that tells a brand’s story, showcases creativity, and features vibrant colors. Unique packaging can also inspire unboxing videos and social media posts.

Cost-effectiveness

Specialty coffee roasting businesses are typically small to medium-sized and must balance labor costs with machine investments. Here’s a breakdown of three common coffee packaging methods used by specialty roasters:

Manual Coffee Packaging

Coffee is weighed manually with a scale or digital weigh, filled into bags/cans by hand, and sealed using a simple heat sealer or lid crimper. Labels are applied manually.

Pros:

- Lowest Initial Investment: Minimal equipment cost (scale, basic heat sealer, scoop).

- High Flexibility: Easily adaptable to different bag sizes, materials, and batch sizes. Ideal for small-batch roasting, specialty coffees, or custom orders.

Cons:

- Highest Labor Costs per Unit: Very labor-intensive, leading to high per-unit labor costs, especially as volume increases or in region with higher wages

- Liminited Production Capacity: including several careful steps, hard to increase speed

- Inconsistent Quality: Susceptible to human error in weighing, sealing, and label application, potentially impacting freshness and shelf life.

- Higher Material Waste: More prone to spillage and imperfect seals, leading to higher material waste.

Best For: Start-ups, very small-scale operations, highly specialized niche products, or businesses with extremely limited capital.

Semi-Automatic Coffee Packaging Machine

Coffee is often automatically weighed/filled by a digital filler with scale, but then bags are manually placed, sealed by another machine, and often labels are applied manually or with a semi-automatic labeler.

Pros:

- Moderate Initial Investment: Higher than manual, but significantly lower than fully automatic systems.

- Improved Efficiency: Reduces labor per unit compared to manual, increasing throughput. One operator can manage multiple tasks or a small team can be highly efficient.

- Better Consistency: Machines ensure more consistent weighing and sealing, improving product quality, freshness, and reducing material waste.

Cons:

- Still Labor-Dependent: While less intensive, it still requires human interaction for placing bags, monitoring, and quality checks.

- Learning Curve: Operators need training to use and troubleshoot the equipment.

Best For: Growing businesses with increasing sales volume, those looking to improve efficiency and consistency, or companies with a consistent product line that can justify the equipment investment.

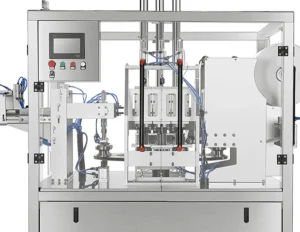

Automatic Coffee Packaging Machine

The machine takes roll stock film (or empty cans), forms the bag/fills with coffee, seals it, and often applies labels – all with minimal human intervention.

Pros:

- Lowest Labor Costs per Unit: Drastically reduces the need for manual labor, leading to significant long-term labor savings.

- Highest Production Rate: Capable of packaging hundreds or thousands of units per hour, ideal for high-volume production.

- Superior Consistency & Quality: Highly precise weighing, perfect seals, and often integrated quality checks ensure consistent product quality, extended shelf life, and minimal waste.

Cons:

- Higher Initial Investment: Relative higher capital requirements than previous methods, but there are also affordable coffee packaging machines on the market from $5000 – $20000

E-commerce

Single-serve pods are the most popular coffee sale type on Amazon, 3 times than others

200% increase in online coffee subscription sales in the past five years.

The U.S.A is the largest market for online coffee purchases

40% of millennials shop coffee online

- 62% of online coffee consumers prefer to purchase from local or independent coffee roasters

Considerations for e-commerce: packaging durability for shipping, visual appeal in online images, effective brand storytelling, and compatibility with subscription models.

Cabinet and Storage Friendliness

Think about how consumers will store your coffee at home. Ensure that your packaging is stable, easy to store, and convenient in shape and size.

How to Pack Coffee for Resale?

Understanding the intricacies of coffee packaging, from material selection to design psychology, is essential for turning your coffee passion into a successful business. For more insights on creating the perfect packaging for your roasted beans, we invite you to explore the extensive resources on our blog. At SANEU, we believe that exceptional coffee deserves exceptional packaging, and we are dedicated to helping you achieve that. Visit our blog at www.saneu.com/blog for detailed guides on effective coffee packaging, ensuring your commitment to quality is reflected in every aspect of

Specialty Coffee Roasters: 8 Factors in designing your coffee packaging

Compostable Coffee Pod Solution:K-cup Manufacturing Welding Machine