As consumer demands shift toward increased convenience, extended freshness, and sustainable options, traditional packaging methods are being evaluated. Flexible packaging has become the mainstream packaging solution. Thanks to advanced pouch packaging machinery, transforming supply chains as well as consumer experiences.

What Exactly is Flexible Packaging?

Flexible packaging refers to packaging materials that can be easily molded, bent, or shaped, contrasting sharply with rigid packaging materials like glass jars, metal cans, or sturdy cardboard boxes.

Flexible packaging typically refers to bags, pouches films, wraps, laminates made out of flexible materials like polyethylene (polypropylene, polyester and other films), foil paper or multilayered structures using materials like the pouch machine as its key component – with flexible pouches becoming one of the more ubiquitous forms of flexible packaging today.

Key Components of Flexible Packaging

Films

These are the foundation of a flexible package, often multi-layered to achieve specific barrier properties. Each layer serves a purpose – strength, printability, heat sealing, or oxygen/moisture barrier, crucial for effective pouch packing.

- Foils: Aluminum foil layers provide excellent barrier properties against light, moisture, and gases, usually used for sensitive food products like coffee, protein powder, or collagen packaged by a pouch machine.

- Paper: While often seen in rigid packaging, paper is increasingly integrated into flexible laminates for rigidity, printability, and a more natural feel, even in some advanced pouch packaging machines

Adhesives

These bond different material layers together, creating robust laminates essential for the integrity of any finished pouch.

Inks & Coatings

For branding, product information, and protective finishes, applied to films

Pre-Made Pouches vs. On-Site Pouch Packing

Pre-made Pouches

Pouch Packaging Machine

When considering flexible packaging, particularly pouches, businesses often face a fundamental choice: should they order pre-made pouches that are then filled and sealed, or should they invest in a pouch packaging machine that forms the pouch from a roll of film on-site and packs products? Both approaches have distinct advantages and disadvantages:

Pre-Made Pouch Filling and Sealing Solutions

Pre-made pouches would arrive at your facility already formed and printed, often featuring features like zippers or spouts. In this scenario, your pouch packaging machine only needs to fill products into pouches – opening an empty pouch, filling it with your product, sealing its top.

Advantages

Aesthetic Appeal

Pre-made pouches often boast superior aesthetic appeal due to being manufactured at specialized facilities with very crisp edges, perfect alignment and more complex shapes (such as highly customized contours) which would otherwise be impossible or near impossible to create on site with traditional forming methods.

Ideal for Liquid Filling

Pre-made pouches are suitable for liquid filling, particularly for products requiring spouts or fitments. The nozzles are typically integrated during the pouch manufacturing process. Your pouch packaging machine only needs to fill and seal, significantly simplifying the liquid filling operation and reducing the complexity of the pouch packing line. This makes them perfect for sauces, purees, beverages, and viscous liquids.

Easier Changeovers & Operation

Changing over between different pouch sizes or styles can be simpler as the machine only needs to adjust for filling and sealing, not forming.

Disadvantages

Higher Material Cost

Pre-made pouches are significantly more expensive per unit than roll film. This is due to the additional manufacturing processes, quality control, and shipping involved in producing and transporting finished pouches.

Storage Space

You need more warehouse space to store bulky, pre-made pouches compared to compact rolls of film.

Less Control Over Pouch Quality

While quality is generally good, you have to rely on your pouch supplier for the integrity of the pouch itself.

Slower Speeds

Generally, fill-seal machines for pre-made pouches operate at slower speeds than high-performance VFFS pouch machines, which continuously form and fill, impacting the overall speed of your pouch packing.

On-Site Pouch Packing (Form-Fill-Seal or VFFS)

The VFFS machines could take a flat roll of film, form it into a pouch shape, fill it with product, and seal it all in an automated process sequence.

Advantages

Lower Material Costs

A roll of packaging film is much cheaper per unit than pre-made pouches, leading to substantial savings for high-volume manufacturers.

Higher Production Speeds

VFFS pouch packaging machines are designed for continuous, high-speed operation, making them ideal for large-scale production where throughput is critical for pouch packing.

Maximized Efficiency

Integrating forming, filling, and sealing into one machine reduces complexity in the overall production line and minimizes potential points of failure.

Optimized Storage

Rolls of flexible packaging film take up much less storage space than pre-packaged pouches.

Greater Control

You have direct control of pouch forming and sealing processes, enabling immediate adjustments or quality checks on the packing of pouches.

Ideal for Long Runs/High Volume

For businesses producing consistent products with large production needs, the FFS pouch machine provides both low per-unit costs and efficiency.

Disadvantages

Initial Machine Investment Cost

Fill and seal machines that fill premade pouches are simpler in their construction; their costs tend to be lower.

Relatively Complex Operation

Operating and maintaining an FFS pouch machine usually requires more experienced staff who understand its inner workings, including film handling parameters, speed, volume

Limited Pouch Shape Flexibility

VFFS pouch machines typically only produce standard pouch styles (pillow, gusseted, block bottom, and quad seal) from flat film material.

Making the Right Decision

Determining whether pre-made pouches or form-fill-seal machines will best meet the specific requirements:

VFFS pouch machines offer efficient pouch packing solutions for large-volume production of dry goods such as powders, granules, or liquids without pre-attached nozzles; providing cost savings on materials while streamlining existing product lines.

Pouch Form Seal Machine

Pre-made Pouch Sealer

Pre-made pouches may be more suitable than ever for liquid products that require integrated spouts, superior aesthetics and/or frequent product switchovers as they utilize fill-seal pouch packaging machines with dedicated fill and seal capabilities to package.

Why Flexible Packaging is Widely Used in the Food Packing

The food packaging, with strict requirements for hygiene, freshness, and shelf life, generally chooses reliable pouch packaging machinery.

Perishable Goods

For items like fresh vegetables, meats, dairy, and baked goods, flexible packaging with high barrier properties is crucial for slowing spoilage, avoiding contamination, and maintaining freshness.

Snacks & Confectionery

From potato chips to soft candies, flexible packaging protects against crushing, moisture, and oxygen, ensuring product integrity and crunch. The lightweight nature also makes them perfect for on-the-go consumption.

Powders & Granules

Coffee, sugar, spices, flour, and instant beverage mixes benefit from moisture-resistant flexible packaging, which directly prevents clumping and maintains freshness

Liquids

Stand-up pouches with spouts are increasingly popular for family-size or commercial use sauces, purees, yogurts, and even spirits, offering convenience and reducing splashing. These specialized pouches are often created by dedicated pouch machines or efficiently filled by pre-made pouch solutions.

Frozen Foods

Flexible packaging for frozen vegetables, meals, and desserts protects against freezer burn and withstands low temperatures without becoming brittle.

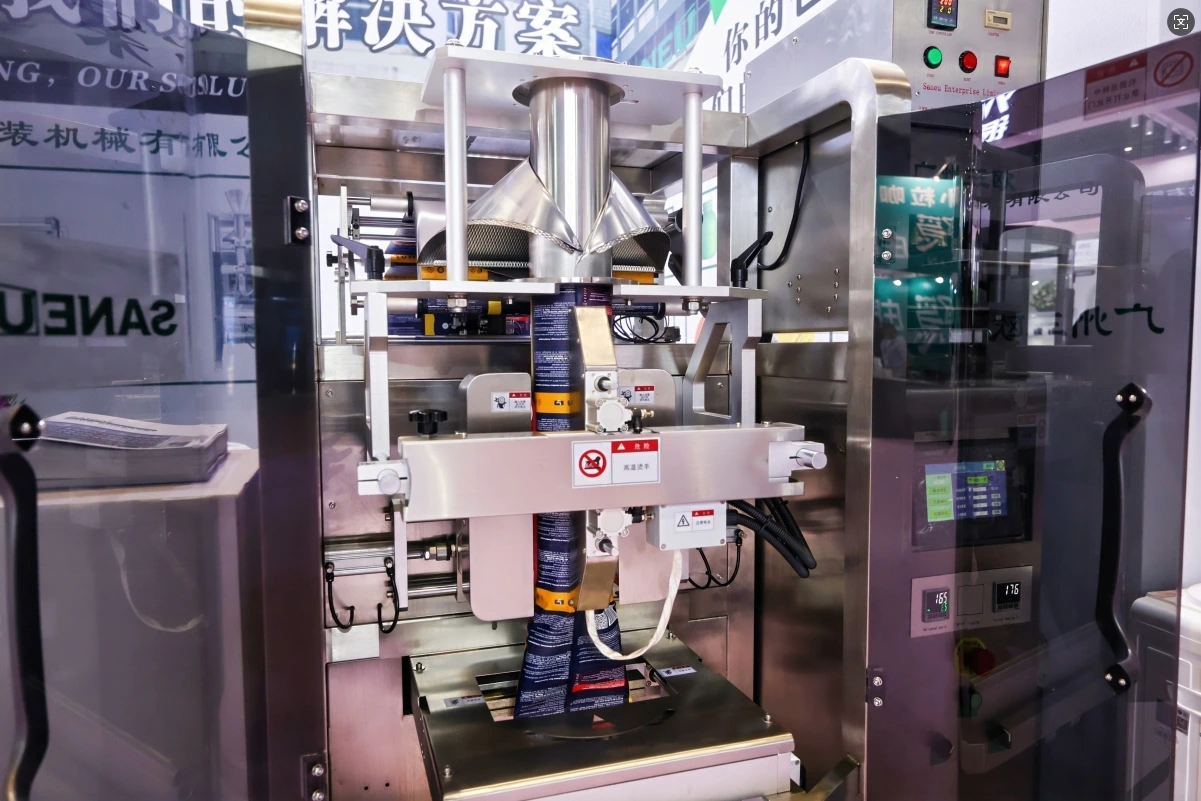

Vertical Form Fill Seal (VFFS) Machines

The pouch packaging machine dominates the North American flexible packing market

It’s the one-step packaging solution for a wide range of food products due to its efficiency and versatility

How a VFFS (Pouch Packing Machine) Works:

- Film Unwind: A large roll of flat, printed flexible film is unwound, the raw material for pouch packing.

- Film Forming: The flat film is drawn over a forming shoulder, which folds it into a tube shape

- Vertical Seal: Heat and pressure are applied to create a continuous vertical seal down the back of the tube, forming the body of the pouch.

- Bottom Seal: Horizontal jaws move in to create the bottom seal of the first pouch (and the top seal of the previous pouch)

- Product Filling: The product (e.g., potato chips, coffee beans, frozen berries, snacks, cereal) is dispensed into the open top of the formed pouch

- Top Seal & Cut: The horizontal jaws then close to create the top seal of the filled pouch, simultaneously forming the bottom seal of the next pouch, and cutting the finished package free. This marks the completion of a perfectly sealed pouch from the pouch packaging machine.

Your Flexible Packaging Partner – Saneu

At Saneu, our decades of expertise come together with forward-thinking strategies so your pouch packing operations remain efficient, effective, and future-proof.

At Food Packaging Solutions we understand the nuances of food packaging – from maintaining product integrity and shelf life, capturing consumer interest, meeting stringent industry standards and meeting stringent food grade specifications. Our VFFS pouch machines and multilane stick pack machines feature precision engineering, robust components and user-friendly controls designed to deliver consistent performance at maximum return on investment in pouch packing.

Saneu can help your business enhance the freshness and convenience of snacks, provide single-serve portions for condiments, or increase market appeal of frozen goods – with flexible packaging solutions and cutting-edge pouch packaging machinery designed specifically to achieve these goals.