In the fiercely competitive coffee market, behind every aromatic cup lies the necessity of efficient and reliable packaging. However, coffee packaging production lines often face numerous challenges: rapid dissipation of coffee aroma affecting flavor, packaging speeds failing to keep pace with roasting rhythms, frequent product changeovers causing efficiency losses, poor sealing leading to leak complaints and returns, material waste driving up costs… These pain points not only impact quality but also directly erode brand profits and market competitiveness.

Precision Analysis: Core Challenges in Coffee Packaging

1. The Battle to Preserve Aroma: The soul of coffee lies in its volatile aromatic compounds. Traditional packaging struggles to completely block oxygen permeation, leading to rapid flavor degradation – especially critical for pre-ground coffee. Standard equipment cannot achieve top-tier low-oxygen environments (e.g., residual oxygen levels <1%), making aroma loss the biggest threat to quality.

2. Efficiency Bottlenecks: When roasting volumes surge (e.g., during seasonal peaks or new product launches), insufficient packaging machine speed becomes a critical bottleneck. Manual or semi-automatic equipment struggles to match output capacity, causing order delays and reduced customer satisfaction.

3. The Agility Challenge: The specialty coffee market thrives on small-batch, multi-variety strategies. Traditional equipment requires frequent parameter adjustments and mold changes for product changeovers, taking 30 minutes or more. This downtime and setup time represent massive waste, severely constraining flexible production.

4. Sealing Reliability Issues: Insufficient seal strength, uneven sealing, or microscopic leaks cause premature packaging failure. Oxygen ingress accelerates coffee oxidation, while moisture invasion leads to clumping. Consumers encounter a subpar experience upon opening, tarnishing brand reputation.

5. The Hidden Cost Culprit: Packaging film materials (especially high-barrier composites) are expensive. Inadequate equipment precision leads to cutting deviations and sealing errors, potentially pushing material waste rates above 5%. Frequent downtime for adjustments and high failure rates further inflate maintenance and labor costs.

The Solution: Smart Packaging Equipment Driving Efficiency and Quality Innovation

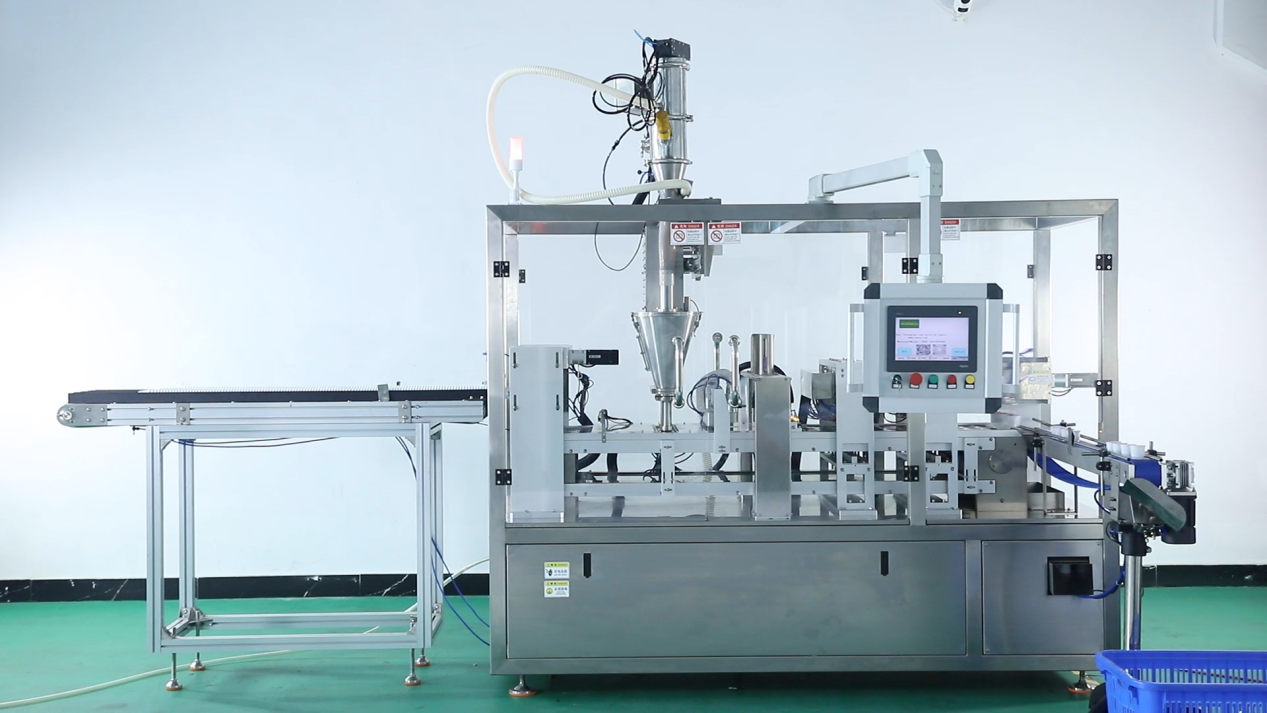

Modern professional coffee packaging machines tackle these pain points head-on with technological innovation:

Ultimate Freshness Solutions:

Ultra-Low Oxygen Preservation: Integrated high-precision nitrogen (or CO2) flushing systems combined with chamber vacuum technology can stably control residual oxygen levels below 1%, even down to 0.5% or lower, significantly delaying oxidation and aroma loss.

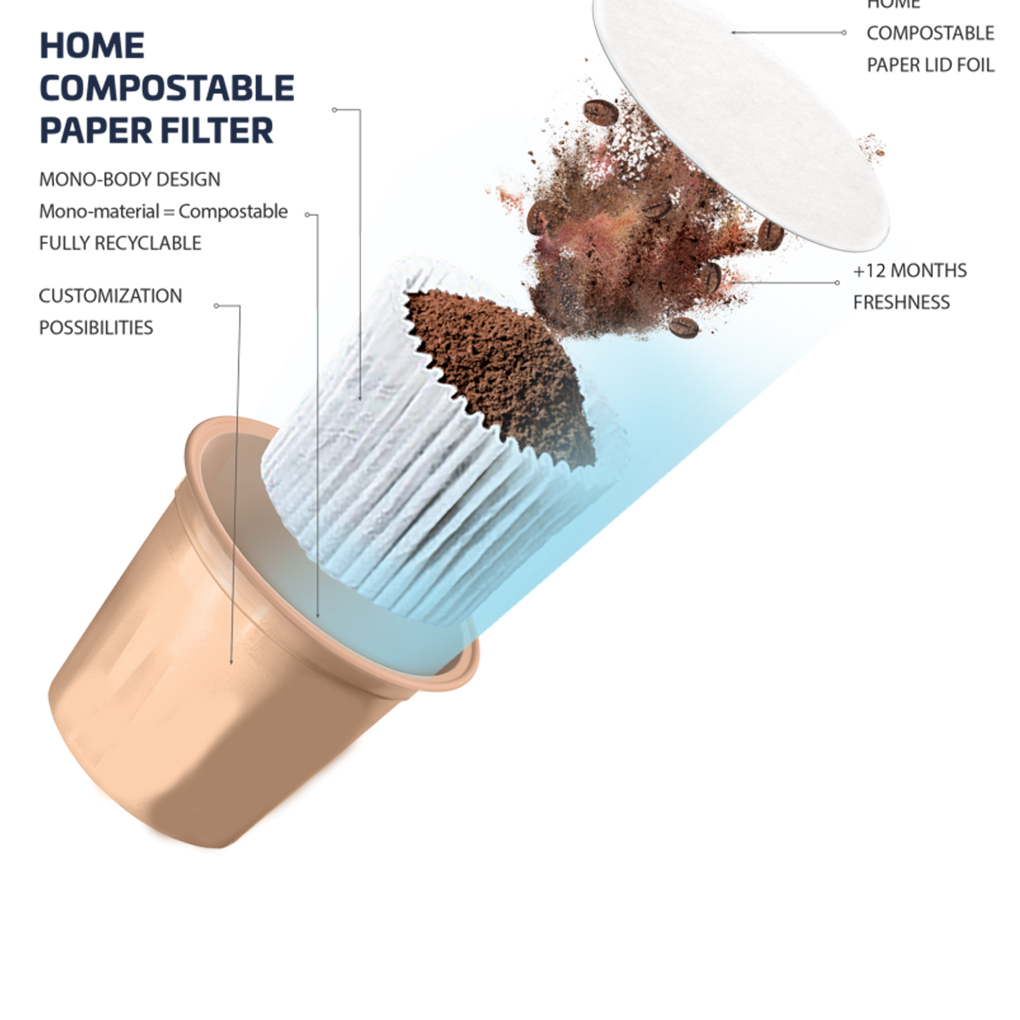

Multi-Layer High-Barrier Film Compatibility: Compatible with aluminum foil, metallized, EVOH, and other high-barrier materials, providing excellent oxygen, moisture, and light barrier properties for a tailored coffee preservation shield.

Breaking the Efficiency Ceiling:

Servo-Driven High Speed: Utilizing servo motors for precise control enables high-speed, stable operation (e.g., 60-120+ bags per minute), easily matching medium-to-large roastery capacities and shortening delivery cycles.

Continuous High-Efficiency Production: Automates the entire process – bag forming, metered filling, gas flushing/vacuum, heat sealing, cutting – eliminating manual bottlenecks and significantly boosting overall packaging efficiency.

Agile Changeovers, Rapid Response:

Intelligent Recipe Management: Stores complete parameter sets for different products (beans/grounds, various weights, different bag styles). One-touch recall during changeovers drastically reduces setup time and errors.

Modular Quick-Change Design: Key components (e.g., formers, fillers, sealing jaws) are modular, enabling rapid disassembly and replacement. Changeover times can be reduced to mere minutes, maximizing equipment utilization.

Technology Ensuring Sealing Reliability:

Precise Temperature & Pressure Control: Dual-loop PID temperature control ensures uniform, stable sealing heat; constant-pressure cylinders or servo pressing guarantee precise, consistent sealing pressure, eliminating weak seals and leaks.

Inline Seal Inspection (Optional): Integrated vision systems or pressure decay testing monitor seal quality in real-time, automatically rejecting defective packs, ensuring zero-defect packaging output.

Precision Cost Management:

High-Accuracy Servo Dosing: Weighing or volumetric filling accuracy within ±0.5g minimizes coffee waste.

Smart Cutting & Registration: Photoelectric registration ensures precise pattern alignment; servo-driven cutting optimizes film utilization, significantly reducing material waste (can be controlled to <2%).

Predictive Maintenance & High Reliability: Key component condition monitoring reduces unplanned downtime; robust design lowers failure rates, significantly optimizing long-term operational costs.

ROI: The Tangible Value of Efficiency and Quality

Investing in advanced coffee packaging machinery is not merely an expense; it’s a powerful growth driver:

Quality Leap: Ultimate preservation capabilities guarantee exceptional flavor from roastery to cup, boosting repeat purchases and brand premium.

Unlocked Capacity: High-speed, efficient production meets growing demand, captures market opportunities, and expands revenue.

Cost Reduction & Efficiency Gain: Reduced material waste, lower labor dependency, and compressed downtime directly increase profit margins.

Agility Competitiveness: Rapid response to small-batch, customized orders helps capture specialty coffee and niche markets.

Brand Protection: Near-zero-defect sealing reliability eliminates customer complaint risks and safeguards brand reputation.

Conclusion: Sealing the Perfect Experience in Every Cup with Smart Packaging

The challenges in coffee packaging are real, but the solutions are equally clear and powerful. Embracing technologically innovative smart packaging equipment is the essential path for coffee brands to break through efficiency bottlenecks, defend exceptional quality, and achieve sustainable growth. Choose packaging technology that precisely matches your needs, transforming every bag of coffee into a promise of freshness, efficiency, and reliable quality. Win the future in the fierce market competition with every cup of impeccable, aromatic excellence.

Solving Coffee Packaging Production Pain Points: Boosting Efficiency and Quality for a Win-Win

In the fiercely competitive coffee market, behind every aromatic cup lies the necessity of efficient and reliable packaging. However, coffee packaging production lines often face numerous challenges: rapid dissipation of coffee aroma affecting flavor, packaging speeds failing to keep pace with roasting rhythms, frequent product changeovers causing efficiency losses, poor sealing leading to leak complaints and returns, material waste driving up costs… These pain points not only impact quality but also directly erode brand profits and market competitiveness.

Precision Analysis: Core Challenges in Coffee Packaging

1. The Battle to Preserve Aroma: The soul of coffee lies in its volatile aromatic compounds. Traditional packaging struggles to completely block oxygen permeation, leading to rapid flavor degradation – especially critical for pre-ground coffee. Standard equipment cannot achieve top-tier low-oxygen environments (e.g., residual oxygen levels <1%), making aroma loss the biggest threat to quality.

2. Efficiency Bottlenecks: When roasting volumes surge (e.g., during seasonal peaks or new product launches), insufficient packaging machine speed becomes a critical bottleneck. Manual or semi-automatic equipment struggles to match output capacity, causing order delays and reduced customer satisfaction.

3. The Agility Challenge: The specialty coffee market thrives on small-batch, multi-variety strategies. Traditional equipment requires frequent parameter adjustments and mold changes for product changeovers, taking 30 minutes or more. This downtime and setup time represent massive waste, severely constraining flexible production.

4. Sealing Reliability Issues: Insufficient seal strength, uneven sealing, or microscopic leaks cause premature packaging failure. Oxygen ingress accelerates coffee oxidation, while moisture invasion leads to clumping. Consumers encounter a subpar experience upon opening, tarnishing brand reputation.

5. The Hidden Cost Culprit: Packaging film materials (especially high-barrier composites) are expensive. Inadequate equipment precision leads to cutting deviations and sealing errors, potentially pushing material waste rates above 5%. Frequent downtime for adjustments and high failure rates further inflate maintenance and labor costs.

The Solution: Smart Packaging Equipment Driving Efficiency and Quality Innovation

Modern professional coffee packaging machines tackle these pain points head-on with technological innovation:

Ultimate Freshness Solutions:

Ultra-Low Oxygen Preservation: Integrated high-precision nitrogen (or CO2) flushing systems combined with chamber vacuum technology can stably control residual oxygen levels below 1%, even down to 0.5% or lower, significantly delaying oxidation and aroma loss.

Multi-Layer High-Barrier Film Compatibility: Compatible with aluminum foil, metallized, EVOH, and other high-barrier materials, providing excellent oxygen, moisture, and light barrier properties for a tailored coffee preservation shield.

Breaking the Efficiency Ceiling:

Servo-Driven High Speed: Utilizing servo motors for precise control enables high-speed, stable operation (e.g., 60-120+ bags per minute), easily matching medium-to-large roastery capacities and shortening delivery cycles.

Continuous High-Efficiency Production: Automates the entire process – bag forming, metered filling, gas flushing/vacuum, heat sealing, cutting – eliminating manual bottlenecks and significantly boosting overall packaging efficiency.

Agile Changeovers, Rapid Response:

Intelligent Recipe Management: Stores complete parameter sets for different products (beans/grounds, various weights, different bag styles). One-touch recall during changeovers drastically reduces setup time and errors.

Modular Quick-Change Design: Key components (e.g., formers, fillers, sealing jaws) are modular, enabling rapid disassembly and replacement. Changeover times can be reduced to mere minutes, maximizing equipment utilization.

Technology Ensuring Sealing Reliability:

Precise Temperature & Pressure Control: Dual-loop PID temperature control ensures uniform, stable sealing heat; constant-pressure cylinders or servo pressing guarantee precise, consistent sealing pressure, eliminating weak seals and leaks.

Inline Seal Inspection (Optional): Integrated vision systems or pressure decay testing monitor seal quality in real-time, automatically rejecting defective packs, ensuring zero-defect packaging output.

Precision Cost Management:

High-Accuracy Servo Dosing: Weighing or volumetric filling accuracy within ±0.5g minimizes coffee waste.

Smart Cutting & Registration: Photoelectric registration ensures precise pattern alignment; servo-driven cutting optimizes film utilization, significantly reducing material waste (can be controlled to <2%).

Predictive Maintenance & High Reliability: Key component condition monitoring reduces unplanned downtime; robust design lowers failure rates, significantly optimizing long-term operational costs.

ROI: The Tangible Value of Efficiency and Quality

Investing in advanced coffee packaging machinery is not merely an expense; it’s a powerful growth driver:

Quality Leap: Ultimate preservation capabilities guarantee exceptional flavor from roastery to cup, boosting repeat purchases and brand premium.

Unlocked Capacity: High-speed, efficient production meets growing demand, captures market opportunities, and expands revenue.

Cost Reduction & Efficiency Gain: Reduced material waste, lower labor dependency, and compressed downtime directly increase profit margins.

Agility Competitiveness: Rapid response to small-batch, customized orders helps capture specialty coffee and niche markets.

Brand Protection: Near-zero-defect sealing reliability eliminates customer complaint risks and safeguards brand reputation.

Conclusion: Sealing the Perfect Experience in Every Cup with Smart Packaging

The challenges in coffee packaging are real, but the solutions are equally clear and powerful. Embracing technologically innovative smart packaging equipment is the essential path for coffee brands to break through efficiency bottlenecks, defend exceptional quality, and achieve sustainable growth. Choose packaging technology that precisely matches your needs, transforming every bag of coffee into a promise of freshness, efficiency, and reliable quality. Win the future in the fierce market competition with every cup of impeccable, aromatic excellence.