Blog

- Home

- Blog

In the fiercely competitive coffee market, behind every aromatic cup[...]

The journey of a delicious confection to a consumer’s delight[...]

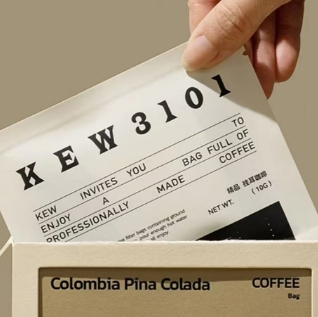

Sachets are small, flexible, usually flat pouches(bags) used to package[...]

How to Package Coffee For E-commerce E-commerce has become the[...]

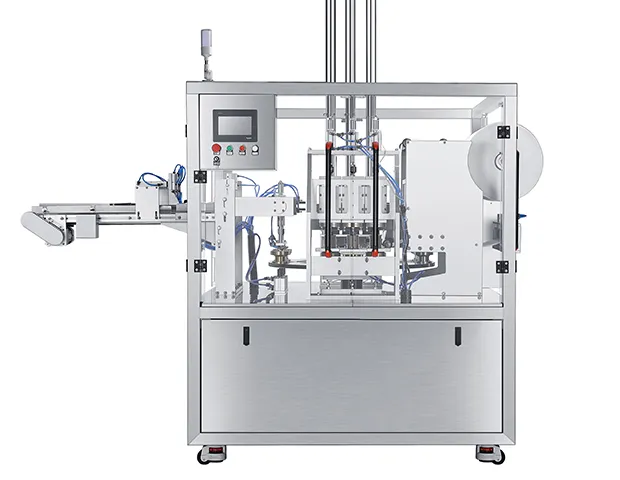

Choosing the right grind coffee pouch packaging machine is a[...]

Many small-batch specialty coffee roasters are skilled and knowledgeable in[...]

Are you a Small specialty coffee roaster? Have you ever[...]

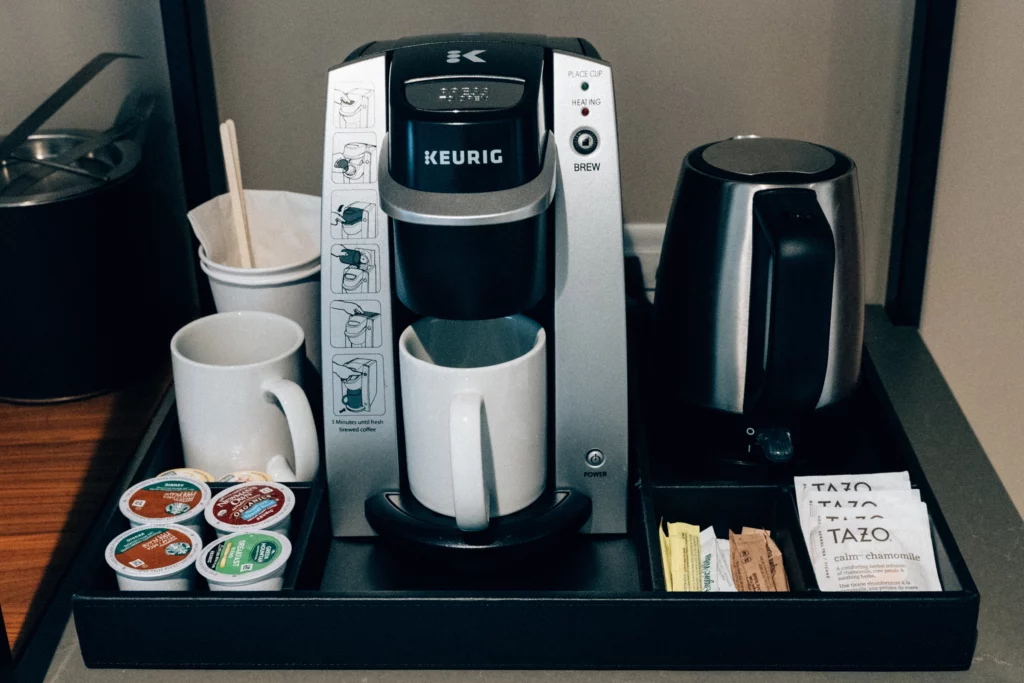

Coffee pods have become an indispensable part of daily brew,[...]

Did you leave your used coffee grounds in the garbage[...]

As consumer demands shift toward increased convenience, extended freshness, and[...]

Keurig’s invention has changed the way we view coffee brewing.[...]

Recently, we learned that Canadian customers are having a hard[...]