Fresh coffee is at the core of every delicious cup you drink, and packaging format plays a pivotal role in protecting its aroma and quality. Yet choosing from among all available coffee packaging solutions can be dauntingly difficult; selecting an optimal one depends on many variables ranging from delicate aromas and freshness maintenance, cost considerations, sustainability goals and consumer convenience needs; this comprehensive guide explores each facet of coffee packaging to provide an in-depth understanding of its protection of this beloved beverage.

As part of your coffee packaging strategy, you might consider the balance between maintaining freshness and appealing to consumers. For examply, empty coffee capsules are specifically designed to preserve bean integrity by featuring airtight seals which prevent oxidation – this ensures each cup brewed features rich aroma and robust flavor consistent across cups brewed. However, the coffee package materials choices also play an integral part; eco-friendly options like biodegradable pouches or recyclable sachets have become increasingly popular among environmentally aware customers.

Material choice aside, the functionality of packaging is of utmost importance. A quality coffee packaging machine can improve efficiency and durability; innovations in design may result in user-friendly features like resealable pouches or single serve sachets that cater to various preferences; ultimately, effective coffee packaging not only safeguards its contents but also attracts wider consumer groups.

The Importance of Coffee Packaging

A primary reason why we need a proper coffee packaging lies in coffee’s susceptibility to external elements that can rapidly reduce the quality, aroma, and tasting, such as oxygen, moisture, light and heat. All types of coffee (ground coffee, coffee beans, green coffee, freeze drying coffee) are especially susceptible to these external threats.

- Oxygen, one of the greatest threats, causes oxidation through chemical reaction that leads to aromatic compound breakdown and leads to flat, stale and often rancid flavors in coffee beans and tea leaves. Imagine vivid fruity notes slowly dissipating into bitterness caused by oxygen; packaging should provide a reliable barrier against this insidious attack.

- Moisture can also pose a threat to coffee beans. Being hygroscopic means they readily absorb moisture from their surroundings and may absorb its aroma and flavor, altering its characteristic aroma and becoming dull and tasteless. Furthermore, too much moisture can lead to mold growth which makes the coffee unsafe for consumption – an effective package must provide an impenetrable barrier from humidity and water vapor.

- Light, particularly ultraviolet (UV) rays, can also do extensive harm to coffee. UV rays can break down delicate oils and organic compounds found in its composition, leading to off-flavors and an overall diminished sensory experience. As such, transparent packaging with no UV blocking properties may not be the ideal way of long-term storage for long-term coffee beans.

- Heat compounds all these harmful processes. While packaging itself doesn’t directly influence ambient temperature, insulation can help minimize temperature fluctuations and mitigate their impacts. Furthermore, packaging designed to preserve freshness at room temperature will have difficulty protecting its contents in extreme heat environments, leading to rapid degradation of quality and shelf life of coffee beans.

- Enhancing Shelf Appeal: Packaging is a vital element of marketing and branding, from protecting coffee products to communicating its quality to potential buyers. Thoughtfully designed packaging can draw consumers in while conveying brand’s story and values.

- Transportation and Return Rate: A strong coffee packaging could resist the breakage and leakage during transportation as well as protect the coffee bean integratiy, which helps control customer return rate.

Coffee Packaging Types

The coffee industry has developed an expansive variety of packaging solutions tailored to various needs, market segments, and aesthetic preferences. Understanding each type is vital for making informed decisions.

Coffee Bags

Bags are among the most widely used coffee packaging options, especially for whole bean and ground coffee. Their popularity stems from their flexibility, cost effectiveness, and ability to incorporate features that promote freshness.

- Materials: Coffee package bags are typically constructed of multi-layered films designed to offer specific barrier properties. Common materials for this application include PET (polyethylene terephthalate) for strength and printability, aluminum foil or metallized films for oxygen/light barrier purposes, LLDPE (linear low-density polyethylene) as a heat sealing and moisture barrier, etc. When combined together these layers form an effective protective shield.

- Advantages: Cost-effective, lightweight, and flexible branding solutions with excellent barrier properties when constructed properly; can include resealable features and degassing valves; punctures are unlikely; rigidity differs significantly from cans; environmental considerations should they not be recyclable.

Coffee Cans

Coffee cans are known for their robust construction, providing excellent protection against light, oxygen, and moisture. Their metal structure ensures that the coffee is well-protected from environmental factors, making them a reliable choice for long-term storage.

- Materials: Typically made from steel or aluminum, cans provide excellent inherent barriers against light, oxygen, and moisture.

- Protection: Their rigid structure offers outstanding protection against physical damage. The hermetic seal achieved during canning provides a near-perfect barrier, significantly extending the coffee’s shelf life.

- Advantages: Excellent barrier properties, long shelf life, durable, highly recyclable. Most coffee cans come equipped with a tight-sealing lid, which plays a crucial role in maintaining the freshness of the coffee. The seal prevents air and moisture from entering, ensuring that the coffee retains its flavor over time. This makes coffee cans an excellent option for those who prioritize freshness.

- Disadvantages: Higher cost than bags, heavier, less flexible in terms of shape.

Coffee Pouches

Coffee pouches offer an efficient solution that combines convenience and freshness.

Resealable Convenience Coffee pouches feature an innovative resealable zipper or closure system, enabling consumers to easily access and reseal their packages, helping ensure fresh coffee after opening them up. This feature can also help preserve freshness after having been opened by keeping air from getting into them and drying out your beans prematurely.

- Coffee Pouch Size Options: Coffee pouches come in various sizes to meet individual consumer needs. From single-use pouches for quick meals on the go to larger bulk storage versions, coffee pouches offer retailers and consumers alike plenty of versatility when it comes to meeting their sizing needs.

- Portability and Storage: Coffee pouches are lightweight and flexible packaging options, making them easy to transport and store, which makes them particularly convenient for consumers who may have limited storage space or who are always on the move. Their portability adds another convenient element to this packaging option for consumers on the go or with limited available space.

Coffee Capsules

These single-serving pods have revolutionized the home coffee brewing experience, prioritizing convenience and portion control.

- Structure: Coffee capsules typically consist of a small cup-like container, filled with ground coffee, and sealed with a foil lid. The most used coffee capsules are K-Cup and Nespresso-compatible coffee pods.

- Materials: are often plastic and aluminum. As consumer awareness of sustainability rises, many empty coffee capsule wholesale companies have invented biodegradable, home compostable, reusable, and recyclable coffee capsules.

- Freshness: The key to capsule freshness lies in their airtight seal. Once sealed, the coffee inside is protected from oxygen, moisture, and light until the moment it’s brewed. Some capsules also incorporate a modified atmosphere within the capsule (e.g., nitrogen flushing) to further extend freshness.

- Convenience: The primary driver behind capsule popularity is convenience. They offer a quick, mess-free way to enjoy a consistent cup of coffee without the need for grinding or measuring.

Considerations Selecting Coffee Packaging

The best coffee packaging involves more than just selecting the container. It also requires a strategic alignment between product needs, market demand, and operational realities. This complex decision is guided by a number of critical factors.

1. Freshness preservation is the most important consideration. Coffee packaging’s primary purpose is to protect coffee from factors that can cause degradation, such as oxygen, moisture, and light.

- Oxygen barrier: The material must have the ability to block out oxygen. The use of high-barrier films that incorporate aluminum foil or EVOH (ethylene vinyl alcohol) is essential to reducing oxidation while preserving coffee’s volatile aroma compounds.

- Moisture barrier: Packaging should prevent moisture from entering the product to keep it at its optimal moisture level, and avoid staleness or mold growth. Moisture barriers include polyethylene and metallized film.

- Light protection: Dark-colored or opaque packaging is preferred for coffee to protect it from UV rays that can damage delicate oils.

- Degassing Valve: A one-way valve is essential for freshly roasted coffee. This valve allows CO2 from the package to escape without letting in oxygen, preventing ballooning. It is necessary to prevent bags from bursting and coffee from staleness.

2. Shelf life: The shelf life of the coffee determines the barrier properties required for the packaging.

- Short shelf life (e.g., local cafes or quick consumption): Allows for less stringent barrier packaging and relies more on rapid turnover.

- Shelf life of medium (e.g. retail grocery): Good barrier properties are required, which can be achieved by using multi-layer films with resealable features.

- Long shelf life (e.g., specialty coffee, exports): Requires superior barrier packaging such as multi-layer high-barrier films or cans with excellent seals to maintain quality for extended periods.

3. Cost: The packaging costs include not only the materials themselves, but also the machinery and the labor required to fill and seal the packages.

- Material Price: Different material prices are different. Aluminum cans, for example, are more expensive than flexible film bags.

- Cost of Manufacturing: The complexity (e.g., number of layers or specialized features such as valves, zippers, etc.) of the packaging influences manufacturing costs.

- Filling & Sealing Efficiency: Packaging machinery’s speed and automation (e.g., coffee capsule filling machine for capsules) have a significant impact on labor costs and production efficiency. Less expensive packaging materials may end up costing more if they require manual or slower filling processes.

- Shipping costs: Lighter packaging can reduce shipping costs, which is important for e-commerce and international distribution.

4. Sustainability: Environmental responsibility is a major factor in brand recognition and consumer choices.

- Recyclability : Materials that are easily recyclable (e.g., aluminum, certain types of plastics) should be used.

- Compostability/Biodegradability: Emerging options include packaging made from plant-based materials that can break down naturally.

- Reduced material use: Reducing the amount of packaging materials used (e.g., by using lighter gauge films or compact designs) contributes towards sustainability.

- Post Consumer Recycled Content: By incorporating recycled materials into packaging, the demand for virgin material is reduced..

5. Branding and aesthetics: The packaging is the first physical contact a customer has with a product. It’s a crucial marketing tool.

- Visual Appeal Design and color palette can be used to communicate brand identity, which in turn attracts consumers.

- Information Delivery: Packaging allows for the inclusion of essential information such as origin, roast dates, tasting notes, and instructions.

- Premium perception: A high-quality package can enhance the perceived value of coffee, even before the coffee is brewed.

- Unique Features: Innovative shapes or textures can help differentiate brands in a competitive market.

Why Choose Coffee Capsules For Coffee Packaging?

In recent decades, the rapid rise of capsules of coffee capsules is testament to its compelling combination of convenience, consistency in quality, and freshness preservation. Coffee pods are the most popular method of home brewing for many consumers. This has led to a major shift in coffee packaging. Coffee capsules have several distinct benefits that drive consumers to choose them.

- Easy Brewing: The capsules make it unnecessary to measure coffee grounds, grind beans, or deal with filters. Inserting the pod and pressing the button is all it takes.

- Time Saving: The ability to make a cup of fresh coffee in less than a minute can be a great incentive for busy people. It’s ideal for daily use because there is no need to clean up coffee grounds or brewing apparatus.

- Portion control: Every capsule contains an exact measured amount of coffee. It ensures consistency in strength and flavor for every brew. This eliminates guesswork and waste. It is especially appealing to those who want a consistent coffee experience.

- Individual packaging: Each capsule is sealed until it is used. The coffee in every capsule is as fresh as it was in the first.

- Modified atmosphere (Optional). Some capsules of high quality go one step further and flush the capsule with an inert gas before sealing. This removes all oxygen from the capsule, creating a more pristine atmosphere for the coffee and extending its shelf-life.

- Exploring Flavors: Customers can switch easily between different roasts and flavors (e.g. espresso, lungo decaf or flavored coffees), catering to a variety of preferences in a home or office.

- Brand Exploration: The capsule format allows consumers to experiment with different brands and blends, without having to make a large investment. This helps coffee producers reach a wider market.

- Self Contained Waste: Used caps are usually easy to discard, and can be placed in a collection bin that is dedicated for recycling.

- Consistent Brewing and Quality: Precision engineering in capsules and brewing equipment ensures an extraction profile that is consistent.

- Optimized Grinding: Coffee capsules are typically ground into a specific consistency that is optimized for the capsule brewing system.

- Controlled parameters: The machine controls the water temperature, pressure, and brewing time. This ensures reproducible results. Consistency is important to consumers who want a consistent coffee experience.

How To Efficiently Package K-Cup Coffee Using Capsule Filling Machines?

Coffee roasters and producers who want to take advantage of the growing popularity of K-Cup coffee capsules should invest in a coffee capsule filling machine and use it effectively. These coffee capsule filling machines ensure precision, consistency, and hygiene in high-volume production. In this context, efficient K-Cup coffee capsule packaging means maximising output, minimising waste and maintaining product quality.

K-Cup Coffee Capsule Feeding and Orientation: The first step is to feed empty capsules into the production line of the machine.

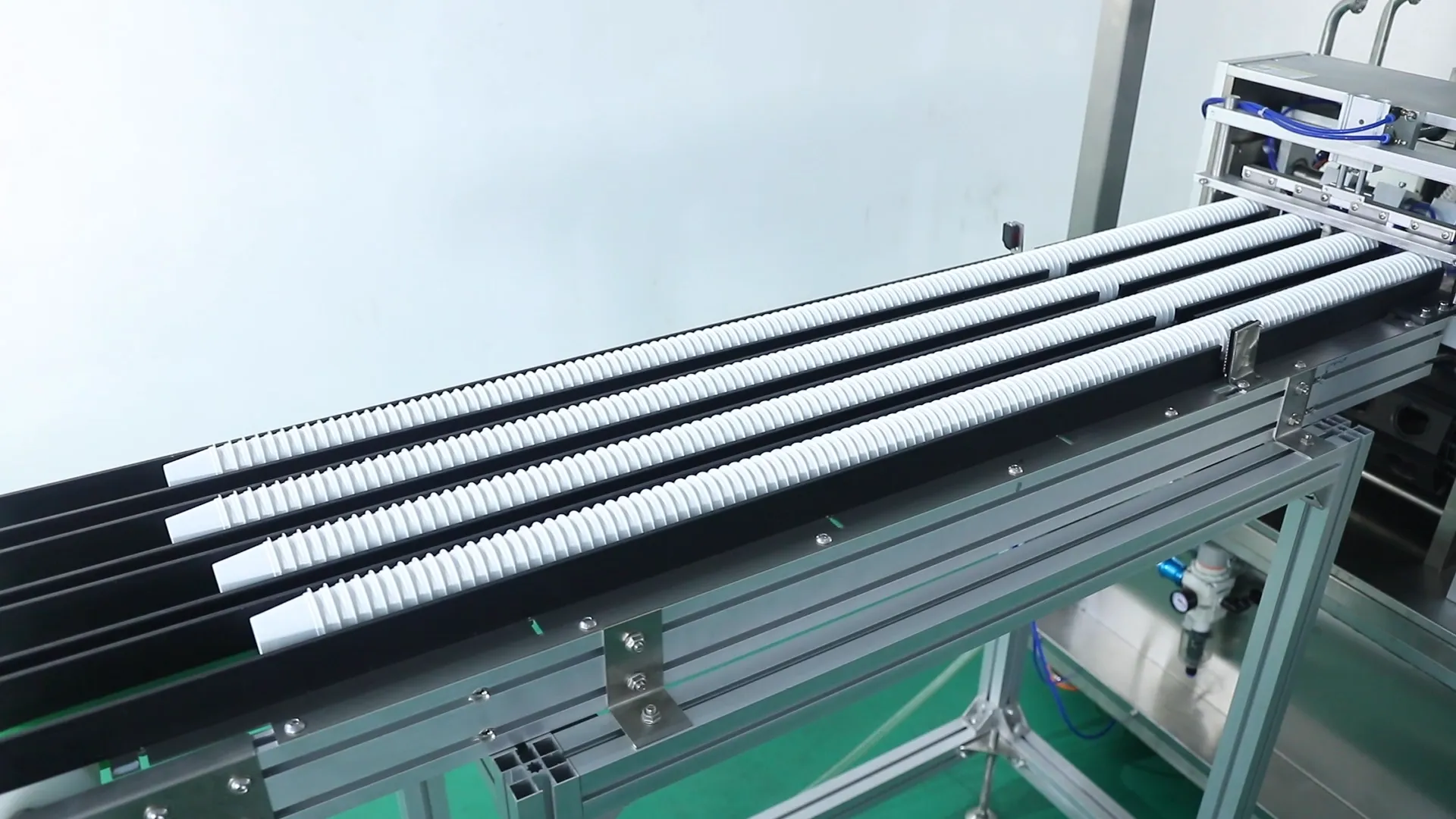

- Modern filling machines for capsules are equipped with automatic feeder systems capable of holding a large number of empty capsules. Empty Coffee Capsules can be guided along a track, and then precisely aligned into pockets or carriers. This ensures that they are in the right position for filling and sealing. Misalignment of capsules would cause machine jams and incorrectly filled capsules. This reduces efficiency.

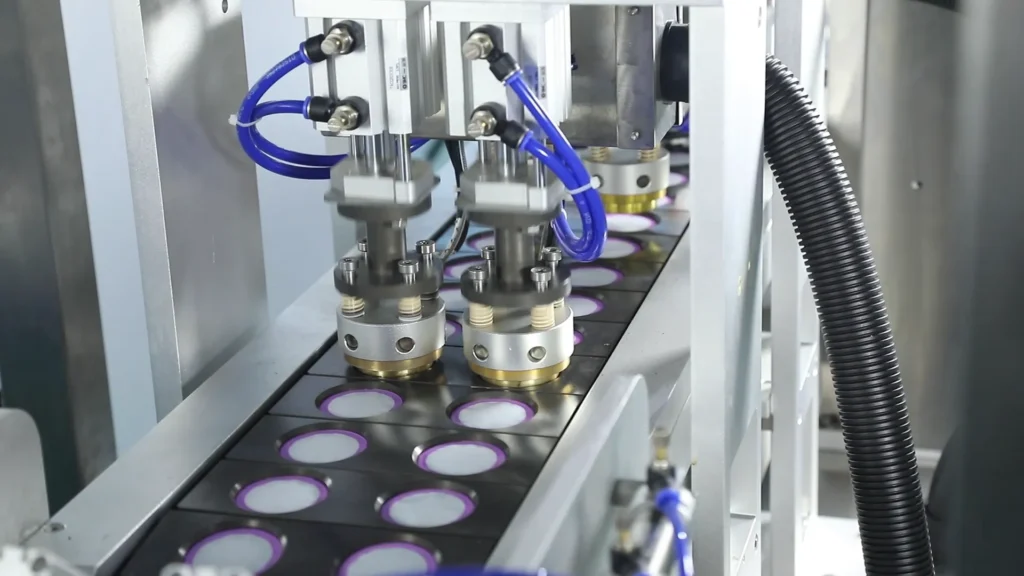

Dosing and filling of coffee capsules: The core operation is where the ground coffee is precisely dispensed in each empty coffee capsule.

- Screw Auger Filling: An auger filler is the most common way to dose ground coffee. An auger rotating in a hopper would push a precise volume of ground coffee into each capsule and ensure consistency in fill weights.

- Nitrogen Flushing (Crucial For Freshness): To ensure optimal freshness, coffee capsules would be flushed simultaneously with inert gas as they are being dosed, which directly removes oxygen from the capsule and creates a modified environment that extends the shelf life of the coffee and prevents its oxidation. This flushing is seamlessly integrated into efficient machines during the filling process.

Tamping (Optional but Recommended): After filling, some machines include a tamping station.

- Purpose: The tamping gently compresses coffee grounds inside the empty k-cup capsule. This creates a uniform puck, which is important for a consistent water flow and optimal flavor extraction. Over-tamping may cause channeling, poor extraction and a weak brew.

- Controlled pressure: Automated systems that apply controlled pressure to capsules, ensuring consistency.

Sealing: A tight seal will help to preserve the freshness of your coffee.

- Heat sealing: This is the most common method of heat sealing the foil pre-cut coffee capsule lid to the capsule rim.

- Induction seal: Some capsule types, such as aluminum, can use induction seals. A magnetic field is used to heat the foil lid and cause it to adhere to the capsule.

- Quality control: Sensors or vision systems are often used to check the integrity of seals and reject final K-cup coffee capsules that have a compromised seal. This prevents product waste and spoilage.

Ejection and Collection: The final step involves discharging the filled and sealed capsules from the machine.

- Automated Ejection: Completed K-cup coffee capsules are automatically ejected from the machine and conveyed to subsequent packaging stages, such as cartoning or bagging.

- Conveyor Systems: Conveyor belts move the finished K-Cup coffee capsules to accumulation tables or directly to secondary packaging equipment.

Extra Lid Capping: After sealing, some capsule designs require an additional lid or cap to be applied.

- Automatic Placement: Machines automatically sort and place secondary lids, which can provide an extra layer of protection, enhance aesthetics, or provide a branding surface.

Key Factors Enhancing Efficiency in Coffee Capsule Packaging

Highly automated machines reduce reliance on manual labor, minimize errors, and maximize throughput.

Precise dosing reduces coffee waste and ensures consistent product quality, improving coffee capsule brewing experience and control return rate.

The nitrogen content level in each packaged coffee capsule affects the shelf life and aroma. The standard requirement is 94% across the coffee packaging industry.

The speed at which capsules are filled and sealed, like capsules per minute, is a direct measure of efficiency.

Start Your Coffee Capsule Business With SANEU

The packaging of coffee is crucial to preserving its freshness and flavor. Our company specializes in innovative packaging for coffee capsules that enhances user experience and protects rich aromas. We use advanced technologies to ensure that each cup of coffee brewed with our capsules has the quality and vibrant taste that coffee lovers expect. We contribute to sustainability by using materials that are eco-friendly, effective and maintain the integrity of coffee.

We offer coffee pouch packaging in addition to capsules to suit the needs of different consumers. These pouches keep the ground coffee fresher for longer, making them a great option for people who like to brew their coffee using traditional methods. We can customise the design, size and functionality of every package using our cutting-edge technology. This will ensure that they are tailored to the needs of your specific brand. The right packaging for your coffee can help you stand out on the shelves and appeal to customers who value quality and sustainability.

How is SANEU Coffee Capsule Produced?

Compatible K-Cup Production Process

Compatible Nespresso Production Process

Compatible Dolce Gusto Coffee Capsules

Explore our collection of videos, showcasing the operation of our coffee capsule packaging machines, where innovation meets efficiency. Witness firsthand how these machines expertly handle various formats, from K-Cup to Nespresso and Dolce Gusto capsules, ensuring that every brew is perfectly sealed and ready for your enjoyment. Each video not only highlights the speed and precision involved in the coffee capsule fill and seal process but also reveals the technology behind maintaining freshness and flavor integrity.