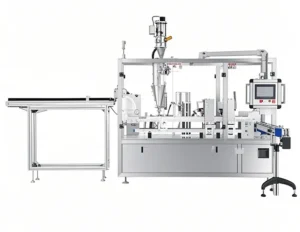

Nitrogen filling of automatic linear coffee capsule filling and sealing machines advantages:

- Preserves coffee freshness: Nitrogen is an inert gas that displaces oxygen, which can cause coffee to become stale. The machine can assist keep the freshness of the coffee for a longer amount of time by filling coffee capsules with nitrogen.

- Prevents oxidation: Nitrogen is an efficient technique to prevent oxidation, which can cause coffee to become rancid. The machine can assist prevent oxidation and keep the flavor of the coffee by filling the coffee capsules with nitrogen.

- Increases shelf life: Because nitrogen filling preserves coffee freshness and prevents oxidation, it can help lengthen the shelf life of coffee capsules.

- Nitrogen filling can assist ensure that each coffee capsule contains the same amount of coffee, resulting in a consistent and high-quality product.

- Reduces waste: By increasing the shelf life of coffee capsules, nitrogen filling can help minimize waste by reducing the amount of spoiled or expired product that must be disposed.

Overall, nitrogen filling is a desirable function for automatic linear coffee capsule filling and sealing machines since it can help preserve coffee capsule quality and freshness, improve shelf life, and reduce waste. Saneu.com has invested heavily in R&D to produce novel packaging for coffee pods that preserves flavor and freshness. We tested nespresso pod, Docle Gusto, Keurig pod , all of their capsules nitrogen content can reach 99.5% plus. The way to unique design with nitrogen flushing chamber was developed by Ken Lee, the founder of our organization. Only our company in China master this core technology with more than 3 years research and lab testing. K cups, which are single-serve coffee pods, are widely sealed in the food and beverage industry using K cup sealing machines. These machines are highly effective and can seal K cups, aluminum Nespresso Capsule quickly and precisely, ensuring that the coffee stays fresh and flavorful for an extended period.

K-cup sealing machines function and the steps

Step 1: Fill the K Cup

Filling the K cup with coffee grounds is the first step in the K cup sealing procedure. The K cup filling machine is used for this purpose, which precisely fills each cup with the required amount of coffee grounds.

Step 2: The machine passes nitrogen over the head space before installing the foil lid.

The foil lid is placed on top of the K cup after it has been filled. The foil lid has a pre-cut hole that permits hot water to pass through it and combine with the coffee grounds.

Step 3: Capping the K-Cup

The next step is to use the K cup sealing machine to seal the K cup. The K cup is placed in the machine, which then uses heat and pressure to seal the foil lid to the K cup’s top. The sealing procedure guarantees that the coffee grounds retain their freshness and flavor.

Step 4: Chilling and Labeling

Once the K-cup has been sealed, it is cooled to room temperature to prevent the coffee from going bad. After cooling, the K cup is labeled with information about the coffee, including roast type, flavor, and strength.

Step 5: Packing

Packaging is the last step in the sealing of K cups. The K cups are placed in boxes or other packaging materials and are prepared for shipment to retail stores, supermarkets, and coffee shops.

In conclusion, K cup sealing machines play a crucial role in the coffee industry, ensuring that coffee remains fresh and flavorful for an extended period of time. The procedure entails filling the K cup with coffee grounds, affixing the foil lid, sealing the K cup with heat and pressure, cooling, labeling, and packaging. The coffee business can efficiently and accurately make high-quality coffee products with the use of K cup sealing equipment.