Coffee Canning Line

- Durabl,Sturdy, and Anticorrosion Exterior Structures

- Highly automatic canning fill seal lines, applied to tin, aluminum, PP, and sustaintable packaging

- Fully certified production lines by ISO, CE, CSA, and RoHS

- Transparency Interface, Simplified Operating Procedures, Lower Maintenance, and Optimized Outputs

- Home

- Canning Line

SANEU's Tailor-Made Canning Solutions for Your Business

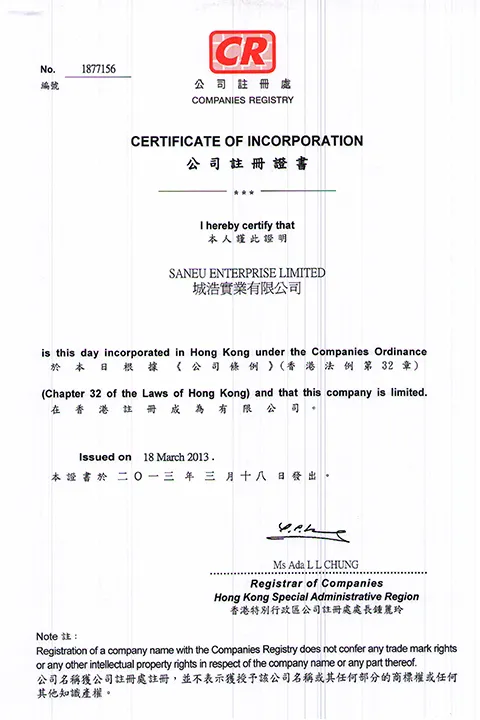

At SANEU, we are committed to designing, assembling, and commissioning high-performance canning lines tailored to your product line’s specific needs, whether Aluminium, PET, or Tinplate made canns. Built with top-grade materials and premium electrical components from trusted global brands, our machines offer full customization to achieve your exact production goals.

Beyond engineering excellence, we ensure your team gets the most out of your investment with comprehensive training and ongoing technical support. From setup to scaling, SANEU is your partner in maximizing efficiency, quality, and reliability in every canning operation.

Flexible Canning Line Solutions to Match Your Product Line

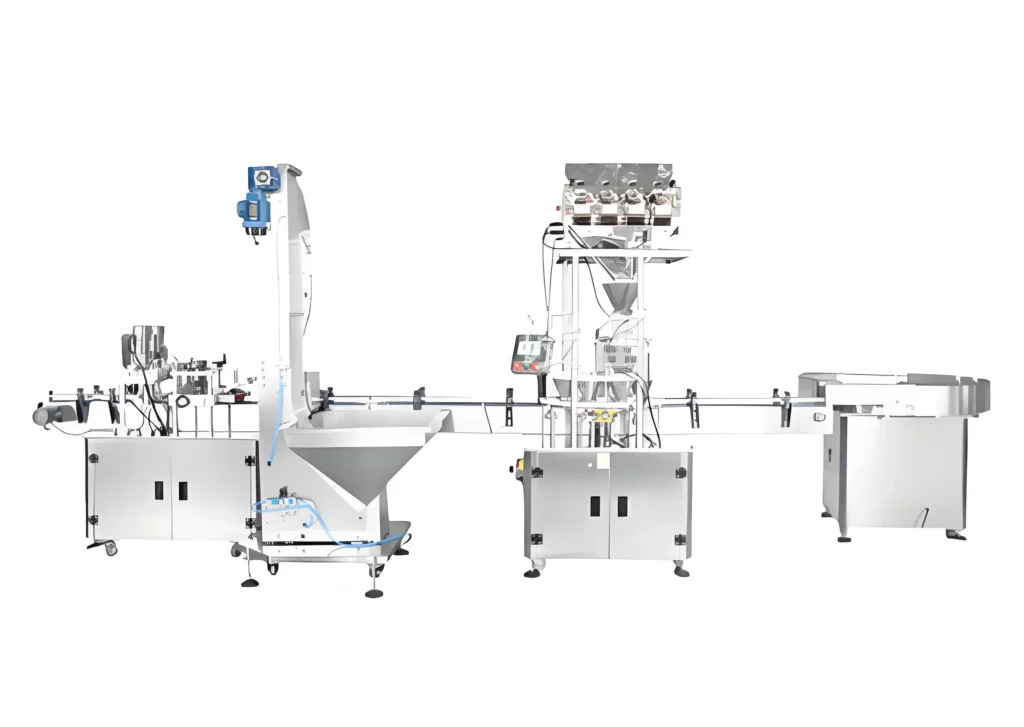

Powder Canning Machines

up to 1800 pcs/hr

± 0.1g filling accuracy

- Seamless Integration: Integrates Cans Infeeder, Sterilizer, Filler, Nitrogen Injector, Sealer, and Capper seamlessly

- Consistent output: rigorous testing ensures the machines meet global standards and maintain canning quality.

- Top-tier Core Components: equipped with branded parts, guarantees high speed and precision performance

- Certified Quality: ISO, CE, CSA, and RoHS certifications ensure reliability.

- Custom Solutions: Tailor powder canning lines to fit your unique needs.

Liquid Canning Machines

Flexible Capacity

Liquid & Sauce

- Accurate filling: the machines use advanced measuring tools to guarantee precise and consistent filling of varioud liquids.

- Full Automation: one-step solutions for can infeed, liquid or sauce filling, and sealing, optional for labeling.

- Customized Solutions: Piston Filling Machines works for packaging sticky products, Gravity Filler for normal liquid

- Intelligent and Efficient: PLC and touchscreen enable automatic adjustments with minimal human interaction when need to package various products

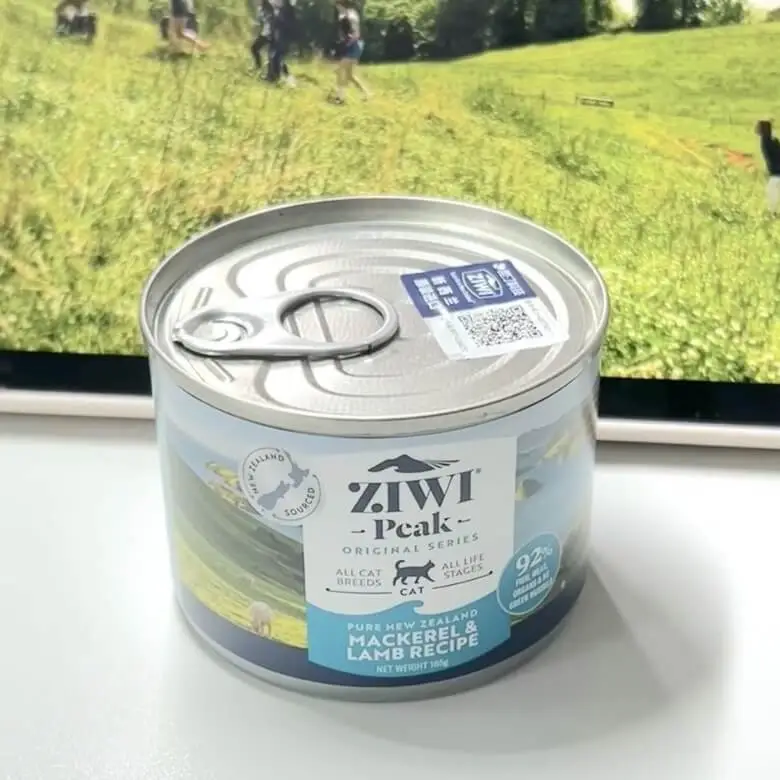

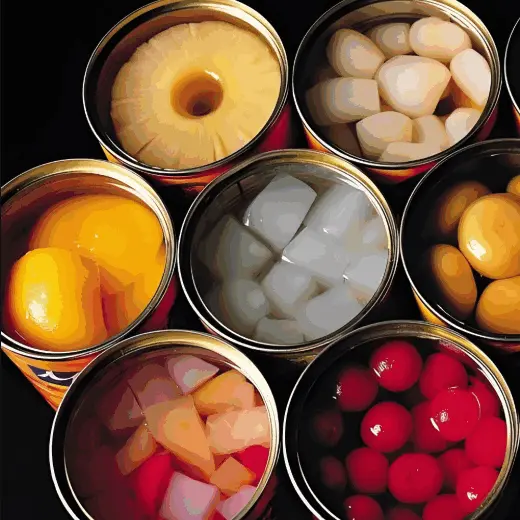

Solid Canning Machines

45 cans per minute

Wide Applications

- Mature Production Line: from cans transportion, cleanning, soli filling to vacuum sealing or nitrogen flushing & sealing.

- Various Inputs: Nuts, Beans, Pickles, Cookies, Tuna, Candies, Tea, and more.

- Tight, Secure sealing: spillproof sealing technology preserves the quality and freshness of its contents.

- Double Protection: sealing and capping working together to minimize the probabilities contamination and spillage

Dependable Canning Lines Built with Superior Components

A machine is but a sum of its parts. To ensure the consistent and lasting performance of our machines, we opt to use the best materials from well-vetted suppliers and branded components from top global brands.

Servo Motors

The integration of servo motors elevates the precision, efficiency, and reliability of the machines while improving their automation capabilities.

Bearings

Keeping the canning process smoothly rolling from step to step, we opt for high-grade and locally sourced bearings that can last for up to 5 years.

Sealing Rollers

To ensure tight sealing, we employ high-grade scroll wheels that can process up to 100 million cans in their life cycle.

Caps Dispenser

Our bottom covers are made from aerospace-grade aluminum instead of electroplated iron to reduce the risks of contaminating the products due to chipping and rusting.

Coffee Canning Machines in Our Catalogue

Why Work with SANEU

Quick Parts Replacement

We always have standard replacement parts in stock and ready for shipping within a day of placing a request.

Comprehensive Training

We utilize a combination of on-site and remote training programs to prepare your team for operating the machine at optimal levels.

Globally Certified Machines

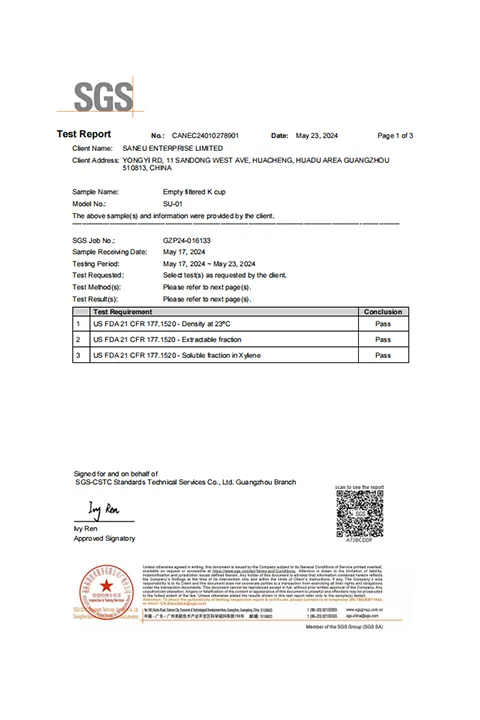

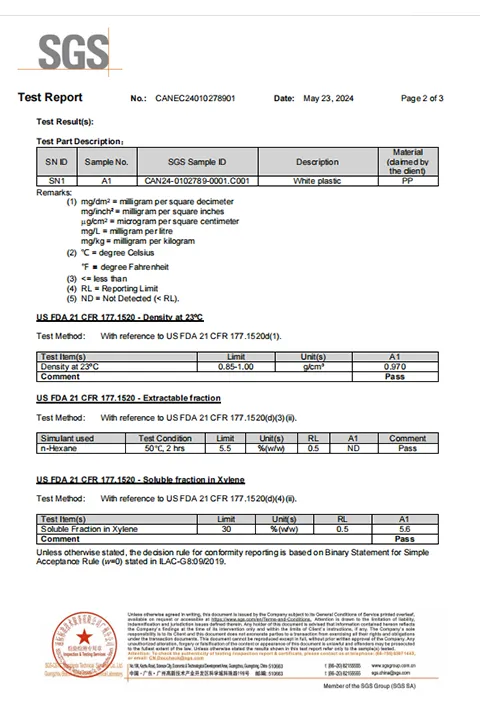

Our machines undergo a series of tests to ensure they meet standards set by CE, RoHS, SCAA, and FDA.

Top-Tier Electric Components

Our machines only use core components from globally known brands like Schneider, Omron, Sigg, Mitsubishi, Yadek, SMC, and Siemens.

Competitive Pricing

Save up to 30% in production costs compared to our peers, thanks to in-house production and a robust supply chain.

Lifetime Technical Assistance

Receive technical support from our expert team throughout the machine’s service life, with video guides showing how to debug the machine within 24 hours of request.

About Coffee Canning Line / Machine

Frequently Asked Questions

All SANEU machines come with a 2-year warranty from the date of receipt. During this period, we offer free replacement and delivery of any damaged spare parts (non-human damage). Additionally, all machines receive lifetime technical support.

Yes, we have distributors in the USA, UK, Italy, Hungary, Thailand, Singapore, Saudi Arabia, Bahrain, Egypt, and Algeria.

We are also actively seeking and welcoming new partners to join the SANEU network.

Our typical production time ranges from 10 to 60 days after customers place orders, depending on the machine models. Some machines are available in stock. Larger automated machines usually require 35 to 45 days for production.

We join major industry exhibitions such as the Shanghai Hotelex Fair, Saudi Gulfood Manufacturing, and Asia Propak every year.

SANEU stands out by offering free solutions for startups and established companies. We provide installation services, free training, and operation guidance for larger machines. Our team also holds annual customer meetings to ensure ongoing support and satisfaction.