Nespresso Filling Machine

- Support packaging coffee pods like Nespresso Original, Vertuo

- Adaptable Vertical and Horizontal Formats for Any Factory Size

- Customizable machines to match specific industry needs

- Electrical core components sourced from well-known brands

- Home

- Coffee Capsule Filling Machines

- Nespresso Filling Machines

Your Reliable Nespresso Filling Machine Provider

Trust SANEU for top-tier Nespresso filling machines, built on decades of industry experience. Our expertise ensures optimal filling and packaging solutions tailored to market needs.

Preserve coffee freshness with high-grade nitrogen sealing and boost efficiency with automated packaging—our machines fit effortlessly into any production line.

Nespresso Filling Machine

SR-11 Nespresso Filling Machine

50-70 K cups/min

±0.1g filling accuracy

- Fully enclosed structure, space-saving design, and a high-speed rotary machine with intuitive features.

- Completely automatic and intelligent machine, simple to get started consistently produces high-quality filled capsules without intensive training, beginner-friendly.

- Made with food-grade 304 AISI stainless steel, ensuring stability and durability. A High-resolution Schneider servo system generates highly accurate positioning, detective sensors reduce production waste.

- Widely applied in filling and sealing liquids and sticky sauces by replacing the screw auger with pumps.

SN-1 Nespresso Filling Machine

nitrogen inside cup up to 99.9%

±0.1g filling accuracy

- Equipped with SANEU's exclusive 99.9% nitrogen-filling device that preserves freshness and aroma maximumly

- Modular design allows for smooth changeover when packaging other-sized coffee capsules.

- Designed with a compact footprint, making them suitable for facilities of all sizes, even those with limited space (less than 20m²).

- Production capacity can reach 2,100 capsules per hour when the nitrogen flushing function is turned off.

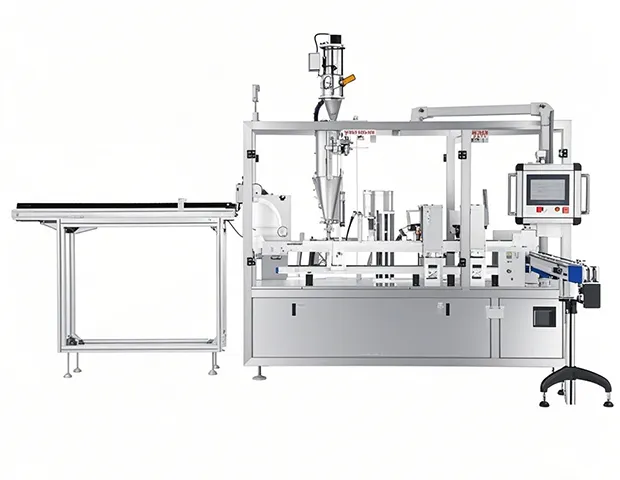

SK-2 Nespresso Filling Machine

100 pcs/min

could connect with cartoning machine

- Compared with the rotary compact machine, the horizontal structure could connect with cartoning machine for upgrading to intelligent production line

- High-quality pneumatic components for even and stable air circulation, greatly improving its production capacity .

- The core electrical system from Schneider. High-resolution servo system, and SMC air cylinder.

- Also supports filling and sealing more powder, granules, and liquid upon customer requests, such as tea, drink mix, dishwasher powder, salad dressing, and yogurt.

- The machine includes top-grade chain wheels, gearboxes, bearings, and dividing boxes that enable fast, stable, and accurate movement throughout the filling and sealing process

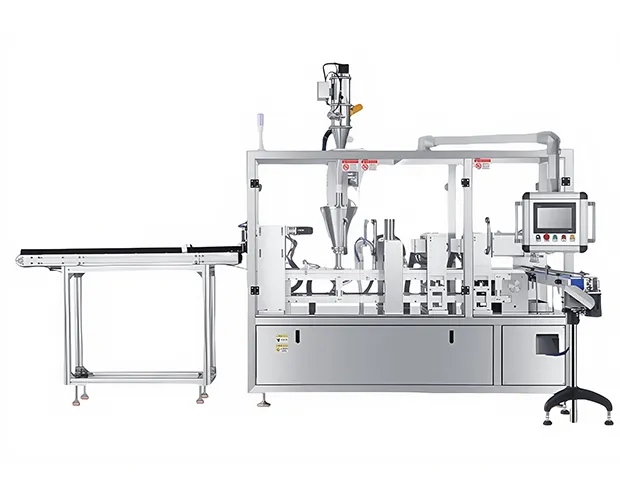

SK-4 Nespresso Filling Machine

maximum capacity 200pcs/min

top-tier system

- 4 cavities working in-line simultaneously to maximize coffee capsule production capacity, the maximum 12,000 pcs per hour

- Inline Weighing System, Schneider electric system & serve motor, Sensor Detection, and food-grade 304 stainless steel frame to achieve stability and durability

- Could package more powder, granules, and liquid upon customer requests, such as tea, drink mix, dishwash powder, salad dressing, and yogurt

- Inline Weighing System, Schneider electric system & serve motor, Sensor Detection, and food-grade 304 stainless steel frame to achieve stability and durability

- Equipped with the latest market technology, a single operator can manage the entire machine. Support integrating with cartoning machine and welding machine for generalizing smart Nespresso production line.

SR-1 Nespresso Filling Machine

beginner friendly auto fill seal

mold changeover

- Capable of filling, sealing, and flushing nitrogen into 1,100 to 1,300 pcs per hour.

- Allows for packaging different capsules sizes and shapes with extra mold parts

- Precise nitrogen gas flushing component ensures that each final capsule contains 98.5% nitrogen level inside

- Affordable choice for start-up coffee roasters to test single-serve coffee product market

Why Partner with SANEU

Tailored Solutions for Your Business

SANEU’s experts collaborate closely with you to design Nespresso filling machines that align with your unique needs and budget, whether you’re a first-time buyer or expanding your operations.

Industry Veterans

Leverage the expertise gained from over 12 years of packaging machine production. Our seasoned team brings a wealth of knowledge and skill to every project, ensuring exceptional results.

Rigorous Quality Assurance

Every machine undergoes thorough functional and performance testing to meet its intended application and surpass market standards, guaranteeing reliability and efficiency.

Comprehensive After-Sales Support

We provide expert assistance through installation and training programs, backed by responsive customer service, ensuring you maximize your machine’s potential and achieve optimal results.

Beyond Coffee Powder

SANEU’s filing machines can handle various packaging, including powders (milk, matcha, hot chocolate), granules(sugar, herbal tea), and liquids (coffee concentrate, peanut butter, syrup, fruit tea syrup), with the same precision, speed, and quality. Besides, we offer private-label Nespresso coffee capsules made of PP, aluminum, and compostable materials.

Machines Videos

SK-2 Nespresso Filling Machine

SK-4 Nespresso Filling Machine

SR-11 Nespresso Filling Machine

About Coffee Capsule Filling Machines

- Coffee Filling Machine, Coffee Packaging News

Frequently Asked Questions

All SANEU machines come with a 2-year warranty from the date of receipt. During this period, we offer free replacement and delivery of any damaged spare parts (non-human damage). Additionally, all machines receive lifetime technical support.

Yes, we have distributors in the USA, UK, Italy, Hungary, Thailand, Singapore, Saudi Arabia, Bahrain, Egypt, and Algeria.

We are also actively seeking and welcoming new partners to join the SANEU network.

Our typical production time ranges from 10 to 60 days after customers place orders, depending on the machine models. Some machines are available in stock. Larger automated machines usually require 35 to 45 days for production.

We join major industry exhibitions such as the Shanghai Hotelex Fair, Saudi Gulfood Manufacturing, and Asia Propak every year.

SANEU stands out by offering free solutions for startups and established companies. We provide installation services, free training, and operation guidance for larger machines. Our team also holds annual customer meetings to ensure ongoing support and satisfaction.