First Time Buyer

- Home

- First Time Buyer

Bringing More Value to Your First Packaging Machine Purchase

Purchasing your first packaging machine is a major decision—one that can significantly impact your business’s long-term profitability. With careful planning and guidance from industry professionals, you can protect your investment and set the stage for long-term success.

If you’re new to automated packaging, choosing the right partner is just as important as choosing the right machine. Look for a manufacturer that does more than just sell equipment. At SANEU, we go beyond production by offering complete support—from initial consultation and needs assessment to user training and post-installation maintenance and repair services.

What sets SANEU apart is our commitment to your success. We’re not just machine manufacturers—we’re your long-term packaging partner. With over a decade of experience, we guide you through every step of the sourcing and setup process, ensuring your first packaging machine purchase is smooth, efficient, and worry-free.

Are You Going to Package

Coffee

Tea

Sugar

Flour

Sour

Honey

Pet Food

And More....

Built Just How You Need It

Working with different businesses over the years, we’ve honed our customization capabilities to create machines tailored for food, medical, skincare, pet food, and other industries. We meticulously identify the right sealing type, pouch material, and machine components you need for precise and consistent packaging per industry norms.

Popular First-Time Packaging Machines

0

Questions to Prepare for

As a guide in creating the perfect packaging machine to your preference, our team typically ask a list of questions during the consultation phase. Get a head start and download our questionnaire to begin your sourcing experience at the right track.

Considerations When Requesting a Packing Machine Quotation

At SANEU, we understand that selecting the right packaging machine is a critical decision for your business. Each machine we offer is tailored to meet the unique demands of our clients’ projects. To ensure we provide you with the most accurate recommendations and a precise quotation, our expert team needs a thorough understanding of your specific production requirements. By sharing detailed information upfront, you empower us to identify the ideal packaging solution that optimizes your efficiency and productivity.

We’ll explore several key aspects of your packaging needs to kickstart this process and guide you toward the perfect machine. Your thoughtful responses to the following questions will enable us to craft a solution that aligns perfectly with your objectives:

- Understanging your products

The very first step in choosing the right packaging machine is to deeply understand the nature of the product that you intend to package. Different product textures require different packaging formats and machines. To assist you effectively, please specify tell us what products you are packaging. Please be as specific as possible. For instance, “ground coffee,” “granulated sugar,” “liquid coffee concentrate”, “sticky sauce,” or “peeled tomato.”

- Powdery Products: If you are packaging powders, please describe their characteristics. Is it very light like salt, or cohesive like flour? Does it tend to cause static problems? Knowing these properties will help us recommend appropriate filling and sealing methods

- Granular Products: For granular items such as beans, rice, coffee beans, grains, popcorn, or seeds, please specify their approximate diameter, size, and shape. This information is crucial for selecting the right feeding and measuring systems.

- Liquid Products: When dealing with liquids, viscosity is a key factor. Is it a thin liquid like water, or a viscous liquid like honey or lotion? It will directly affect the choice of filling pumps, like ceramic pumps or peristaltic pumps.

- Package Format

The way you intend to present your product significantly impacts the type of packaging machine required. We offer a wide range of packaging formats to suit various marketing and practical needs.

- Diversified Single-serve Coffee Capsules/Cup: For individual and small portion servings, we highly recommend coffee capsules since they can maintain freshness to the greatest extent and are widely applied for packaging powder, granules, and liquids. Besides, we also provide private-label coffee capsule customization services from lids to capsules, allowing you to create a unique brand presentationz

Empty Alu Nespresso Pods

K-cup with Filter

Dolce Gusto

Customized Design

- Pouches and Sachets: Offering flexible packaging options, our machines can handle a variety of pouch styles (e.g., flat, stand-up, gusseted) and sachet formats for powders, granules, and liquids, providing cost-effective and customizable solutions. We also support filling multiple volumes through one machine by simply changing the settings, offering enhanced versatility.

Pollow Bag

Gusset-Bag

Pillow Gusset Bag

Sachet

- Stick Pack: Designed for single-serving portioning, stick packs are long, narrow, and tubular packets sealed on both ends, commonly used for powders, liquids, and granules. Our multi-lane stick pack machines combine filling, measuring, bag forming, sealing, batch printing, counting, and product discharge into a single system. These machines are engineered for efficient packaging in industries like food, beverage, cosmetics, skincare, and dietary supplements

Powder Stick Bag

Jelly Stick Pack

Lqiuid Coffee

Single-serve Sugar

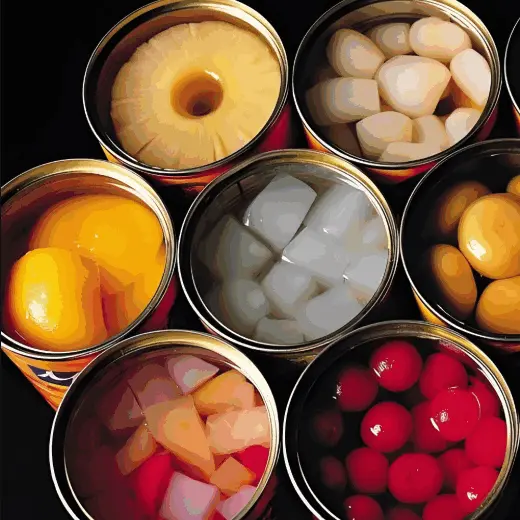

- Cans: Our can packaging solutions are ideal for liquid, powder, and granule products, particularly when bulk or large-size packaging is required. Cans offer a cost-effective packaging option. We offer machines and lines that perform every function in can packaging, from can sterilizing and filling to seaming, labeling, and coding. A key consideration with cans is that the entire contents are typically intended for use after opening. Besides, we offer glass, aluminum, PP, and tin cans for fitting most products’ packaging needs.

Tomato Sauce

Roasted Nuts

Fruit

Oil Fish

- Production Demands and Packaging Speed

Your desired production output is a critical factor in selecting a machine with the appropriate speed and capacity. We offer machines ranging from entry-level models with semi-automatic operations for small-scale manufacturing to fully automatic high-speed systems for large-scale production. Please specify your target production demands and desired speed. Low Speed: Suitable for small businesses or niche markets with lower volume requirements. Moderate Speed: Ideal for growing businesses with increasing production demands. High Speed: Designed for large-scale industrial operations requiring maximum output and efficiency.

- Detailed Product Specifications and Testing

To realize seamless operation and accurate packaging results, we hope that you could provide specific details about your product. Providing samples benefits our technical team to conduct thorough testing and guarantee the compatibility and performance of the recommended machine. What exactly is the product? Can you provide us with a sample for testing? Solids? Liquids? Powders?

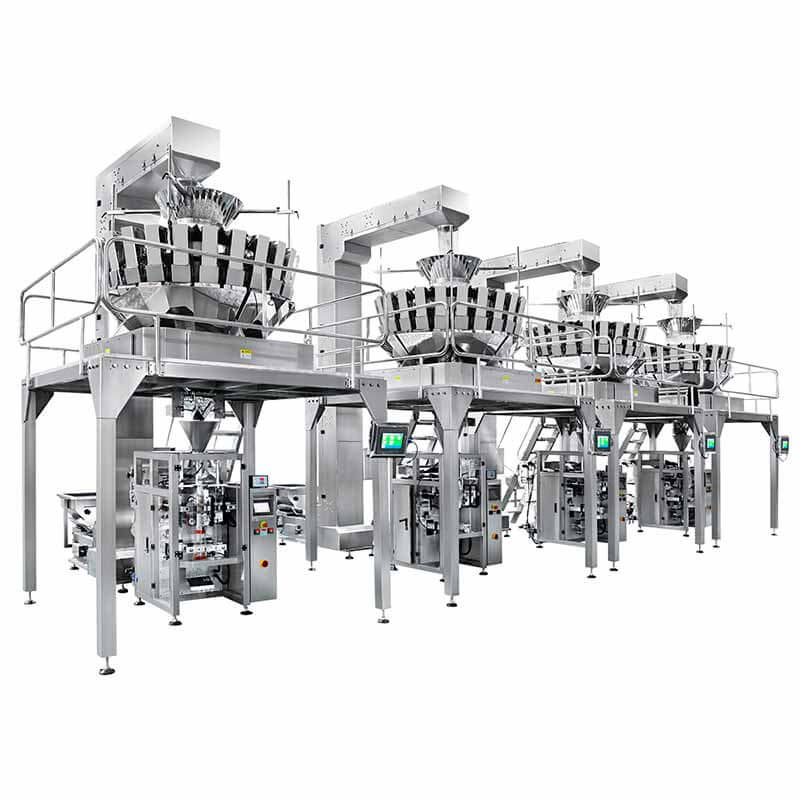

- Customization and Production Lines

Beyond individual packaging machines, we also specialize in creating integrated production lines tailored to your specific workflow. If you require a comprehensive solution that includes additional equipment, please let us know. Are you looking for a standalone packaging machine, or do you require a complete line that includes equipment for product feeding, conveying, labeling, cartoning, or palletizing? Describing your overall production process will enable us to design a seamless and efficient integrated solution.