SANEU Manufacturing

Coffee packaging machine production, refined and streamlined by SANEU’s experts.

- Home

- SANEU Manufacturing

World-Class Manufacturing and Quality

SANEU has honed its capabilities in manufacturing top-tier custom packaging machines for more than a decade, distilled in each machine that leaves our warehouse.

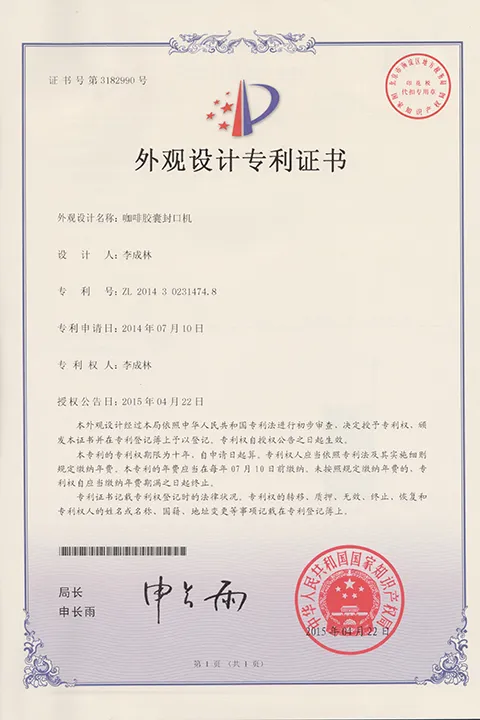

Backing our production prowess is a 3000㎡ facility with multiple workshops to handle each part of the manufacturing process. The facility secured certifications from CE and RoHS, And multiple patents.

For small machines, we have a standardized production process that guarantees quick and consistent output. For larger machines and production lines, we offer comprehensive custom solutions that are tailored specifically to your needs.

Sourcing Mechanical Components from The Best Brands

As each machine is a sum of its parts, only using the best components results in reliable and consistently performing packaging machines.

Schneider (France)

Mitsubishi (Japan)

SMC (Japan)

Sigg (Germany)

Omron (Japan)

Yadek (Taiwan)

Siemens (Germany)

Where Ideas Turn Into Reality

We create the mechanical components of each packaging machine using precision laser and bending equipment for stainless steel parts.

We also utilize the latest lathes and milling machines to produce aluminum components.

To achieve a lasting stainless-steel shine, we combine skilled craftsmanship with both manual and automated polishing. Though time-intensive, this process significantly enhances the machine's value. Once components are ready, our team carefully assembles and inspects each step to ensure precision and minimal adjustments. Final debugging ensures optimal performance and error-free operation.

Nitrogen Content in Nespresso and K-Cup and Accuracy Testing on Rotary Single Pod Machine

SANEU utilizes cutting-edge German-made Oxybady testing equipment to detect nitrogen content with utmost sensitivity, ensuring the highest precision in our coffee capsules. The cup weight is meticulously measured using a state-of-the-art machine auger.

known for its exceptional accuracy in powder filling. With this advanced technology, we guarantee the quality and precision that coffee enthusiasts deserve in every pod.

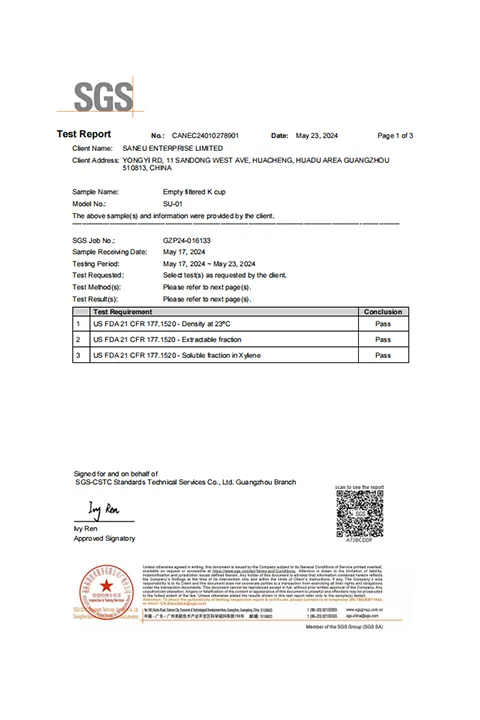

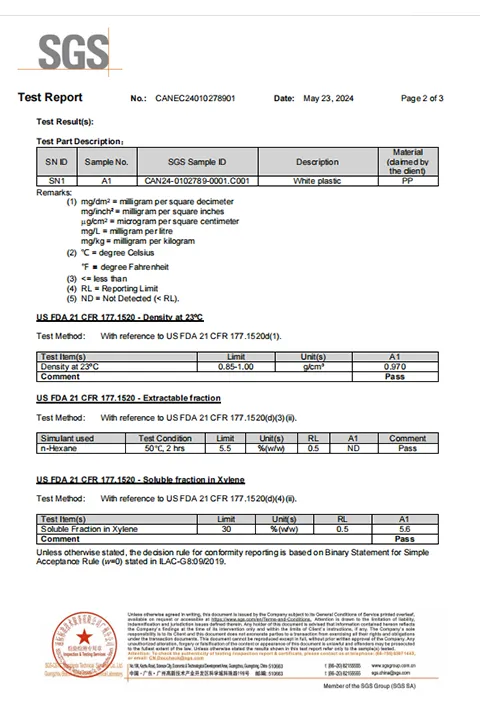

Comprehensive Testing

Functional Testing

Each machine undergoes a series of functional tests to verify performance, include loading/unloading, speed and accuracy checks, and safety system evaluations.

Performance Testing

At this stage, the machine’s overall performance is evaluated—focusing on efficiency, productivity, and compliance with industry standards.

Packing Speed Test

During this test, our quality experts assess the machine’s performance under different operating conditions, meets the desired packaging speed and output.

Weighing Accuracy Test

The machine’s scales are carefully tested to ensure precise weighing within acceptable tolerances for each package.