Stick Pack Machine

- Film unwind and film tension control

- Siemens PLC System, Independent Temperature Control

- Film slitter and forming tubes - set per bag size

- High-speed Production, Space-saving, and Low Maintenance

- Home

- Stick Pack Machine

Custom Stick Pack Machine Manufacturer

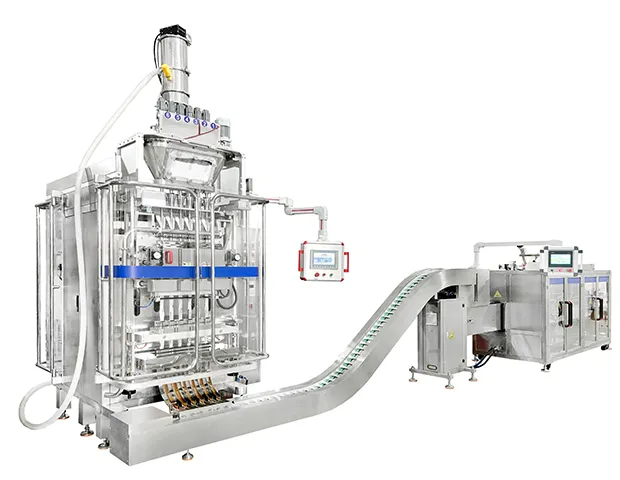

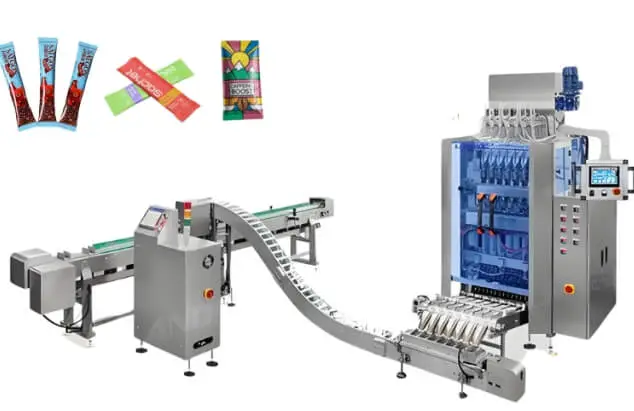

SANEU is committed to designing and developing functional intermittent/ countinuous motion stick pack packaging machines. Each multilane machine combines multiple functions into a single system, including filling, measuring, bag forming, sealing, batch printing, counting, and product discharge. Featuring a compact vertical design, they ensure a smaller footprint, reduced energy consumption, lower labor costs, user-friendly operation, and superior production efficiency.

We offer 4–10 lane stick pack and sachet packaging machines engineered for efficient packaging of liquids, powders, and granules with versatile sizes—ideal for industries such as food, beverage, cosmetics, skincare, and dietary supplements. Packaging outputs’ width can be customized based on customer requirements, ensuring flexibility for diverse production needs.

Automatic Vertical Form Filling Machine Choice

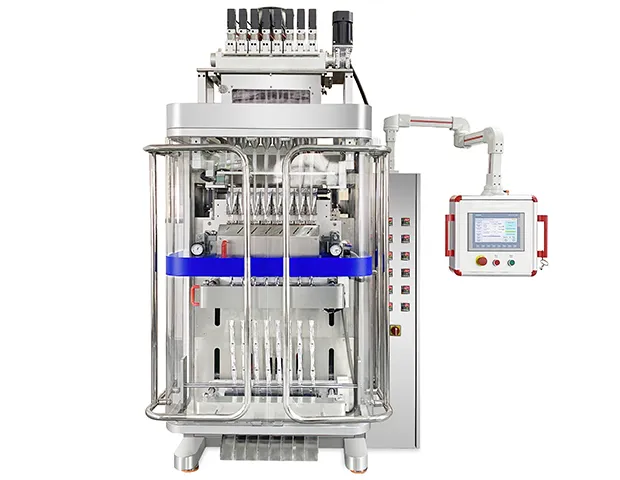

520 Stick Pack Machine

- Durable and Compact Design: Crafted from 304 stainless steel, space-saving, 4-10 lanes, and maximum film width 520mm. The machine is designed for robustness and longevity, suitable for packaging a wide range of products including powders, granules, solids, liquids, and pasty.

720 Stick Pack Machine

- Advanced Safety and Operation: Designed to produce both stick packs and 4-side sealed sachets with lengths ranging from 35–90 mm upon customer requests.Equipped with safety features that align with enterprise safety management requirements, ensuring a secure operation environment.

820 Stick Pack Machine

- Premium Electrical Components and Controls: High-quality electrical components from renowned brands- Siemens PLC control and a user-friendly touchscreen interface, 4–12 lanes continuous motion, integrating together for filling larger content into stick packs.

960 Stick Pack Machine

- Precise Control for Optimal Sealing: An independent temperature control system ensures accurate and stable sealing, producing smooth, consistent, and visually appealing packaging. The premium structural design provides a flatter sealing surface—perfect for showcasing your printed package design with greater clarity and impact.

1200 Stick Pack Machine

- Automated Adjustment and High-Speed Operation: Capable of 4-12 lines packing according to maximum film width of 1200mm, with automated adjustments for servo clamping film, film pulling, and color code control via touchscreen. This facilitates simple operation for sealing and incision deviation corrections, achieving high-speed and efficient production lines

How to choose Stick Pack Machine?

Stick packs are narrow, tubular, single-serve packets sealed at both ends, suitable for powders, liquids, and granules. Their design can reduce secondary packaging costs without losing content volume. After filling and sealing, sensors cut individual packs based on eye marks. These are then batched or conveyed for further packaging.

When choosing a stick pack machine, manufacturers should consider:

- Material type (powders, liquids, or granules)

- Fill volume per pack

- Required production capacity

- Desired pack dimensions and design

Features of Stick Pack Machine

Saneu stick pack machines allow for quick and precise packaging of single-serve products, ensuring consistent manufacturing levels.

High Output

As a multi-lane machine, it can produce up to 600 sticks per minute, perfect for high-output projects.

Quiet Operation

Functioning at levels under 70 dB, our stick pack machines guarantee smooth production while minimizing equipment wear.

Efficient Use of Packaging Materials

A stick pack uses 30% less packaging material compared to most four-sided sachets, reducing cost savings and less environmental waste.

Packaging Variety by Machine Type

Benefits

Top-Notch Components

SANEU only uses the top-tier parts to manufacture your stick pack machines. Sourcing electrical components from renowned global brands like Schneider Mitsubishi guarantees reliability and superior performance.

Affordable Machine Construction

We manage manufacturing costs thanks to in-house production and an established supply chain. Our stick pack machines cost 30% less while maintaining the same features.

On-Demand Support

Machines come with lifetime technical assistance through expert technicians who diagnose the problem and provide detailed video guides to help end-users resolve equipment concerns within 24 hours.

Shorter Equipment Downtime

To minimize production delays caused by equipment downtime, we have replacement parts in stock and ready for shipping within a day from order request.

Equipping Your Team for Success

Along with remote training programs, we can have your technicians visit our factory, understand how the machines work on-site, and document processes via photo or video.

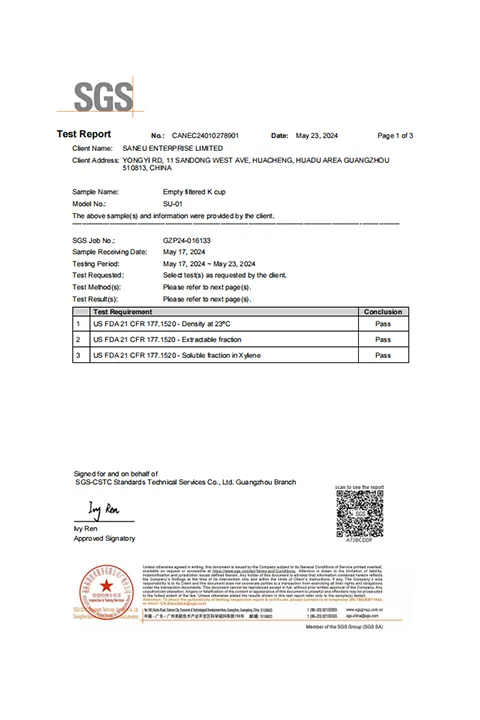

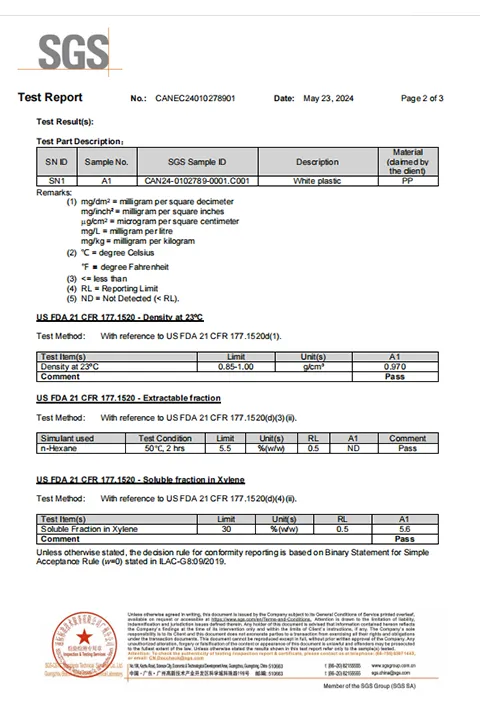

Tested Per Global Standards

Ensuring the stick pack machines adhere to global benchmarks, they undergo numerous tests according to CE, RoHS, SCAA, and FDA requirements.

Words are Good. Examples are Better.

More About Stick Packaging Machines

Frequently Asked Questions

All SANEU machines come with a 2-year warranty from the date of receipt. During this period, we offer free replacement and delivery of any damaged spare parts (non-human damage). Additionally, all machines receive lifetime technical support.

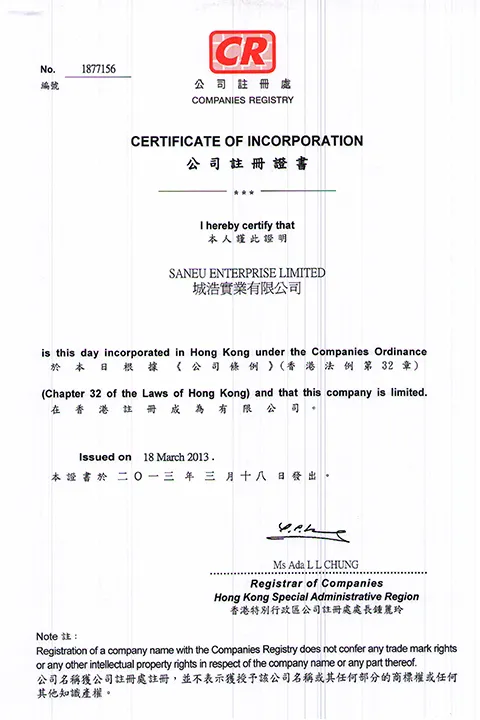

Yes, we have distributors in the USA, UK, Italy, Hungary, Thailand, Singapore, Saudi Arabia, Bahrain, Egypt, and Algeria.

We are also actively seeking and welcoming new partners to join the SANEU network.

Our typical production time ranges from 10 to 60 days after customers place orders, depending on the machine models. Some machines are available in stock. Larger automated machines usually require 35 to 45 days for production.

We join major industry exhibitions such as the Shanghai Hotelex Fair, Saudi Gulfood Manufacturing, and Asia Propak every year.

SANEU stands out by offering free solutions for startups and established companies. We provide installation services, free training, and operation guidance for larger machines. Our team also holds annual customer meetings to ensure ongoing support and satisfaction.