1200 Stick Packaging Machine

Capacity:30-45 cycles/min

Sealing Type:4 side sealing

Sachet Size: 45-160mm L, 35-90mm W

- Constructed from 304 stainless steel for long-lasting use and suitability with various products.

- Integrated with essential safety features to meet enterprise safety standards.

- Equipped with Siemens PLC control for stable and efficient machine operation.

- A spacious, flat packing surface supporting double-sided printing for showcasing your packaging design and branding.

Features

- Independent Temperature Control System: ensure accurate sealing and guarantee smooth, high-quality packaging for every product.

- Servo Motor Metering: Utilizes independent servo motor metering for precise control of the filling process, enhancing the accuracy and consistency of packaging.

- Touch Screen Interface: Features a touch screen interface that allows for easy operation and quick adjustments, enhancing user experience and efficiency.

- High-Speed Operation: designed for high-speed production, enabling the packaging of large quantities in a short amount of time, which is particularly beneficial for industries requiring fast-paced, high-output operations, such as the food and beverage sector, pet food, and supplementary products.

- Integration with Automation Systems: Can be seamlessly integrated with subsequent dosing lines and automatic cartoning machines, enabling a fully automated production line for enhanced productivity and efficiency.

- Fully Automatic Working Processes: The storage bin features continuous automatic vacuum feeding, while the system integrates automatic filling, measuring, bag making, sealing, batch printing, counting, and finished product output.

- Visual Appeal: The flat, uniform surfaces on both sides provide ample space and precise alignment for high-quality graphics, branding, and product details—making 4-side seal sachets ideal for premium and retail-ready packaging.

- Diversified Filling Solutions: Auger, volumetric, or multi-head weigher for powders, granules, and solids; and peristaltic, piston, or ceramic pumps for liquids and pastes. It can accommodate a variety of products—powders (like coffee and powdered drink mixes), granules, liquids (such as oils and syrups), and pastes.

- Flexible Packaging Format Options : Quick product changeovers minimize downtime, making it ideal for manufacturers who need to switch between products swiftly, as long as the sachet size remains within range.

Specifications

| Lane number | 4-12 |

| Powder Filling | Auger filling by servo motor |

| Granule Filling | volumetric cup/weigher |

| Liquid Filing | Peristaltic pump/Pistonpump/Ceramic pump |

| Capcity | 30-45 cycle/min |

| Film width&Thickness | Max:1200mm,0.06-0.01mm |

| Sachet Size | L:45-180mm w:35-120mm |

| Sealing Type | 4 side sealing |

| Cutting Type | 1.straing cutting 2.zig zag cutting 3.Continuous cutting |

| Voltage | AC380V Three phaase,Ac220v Single phase cutting |

| Size & Gross Weight | 2200X1600X2800MM 1200Kg |

Application

Supplement Powder

Drinking Powder

Coffee Powder

Dry Pet Food

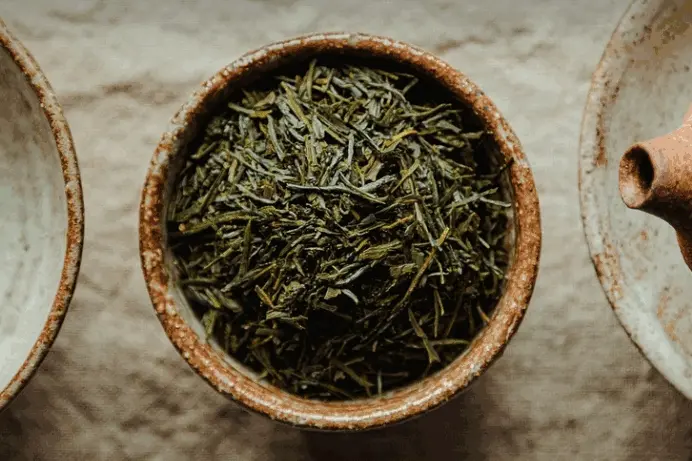

Loose Tea

Sea Salt

Nut

Grains

Stick Bag Type