Comprehensive Guide About VFFS Machines

Introduction

Introduction

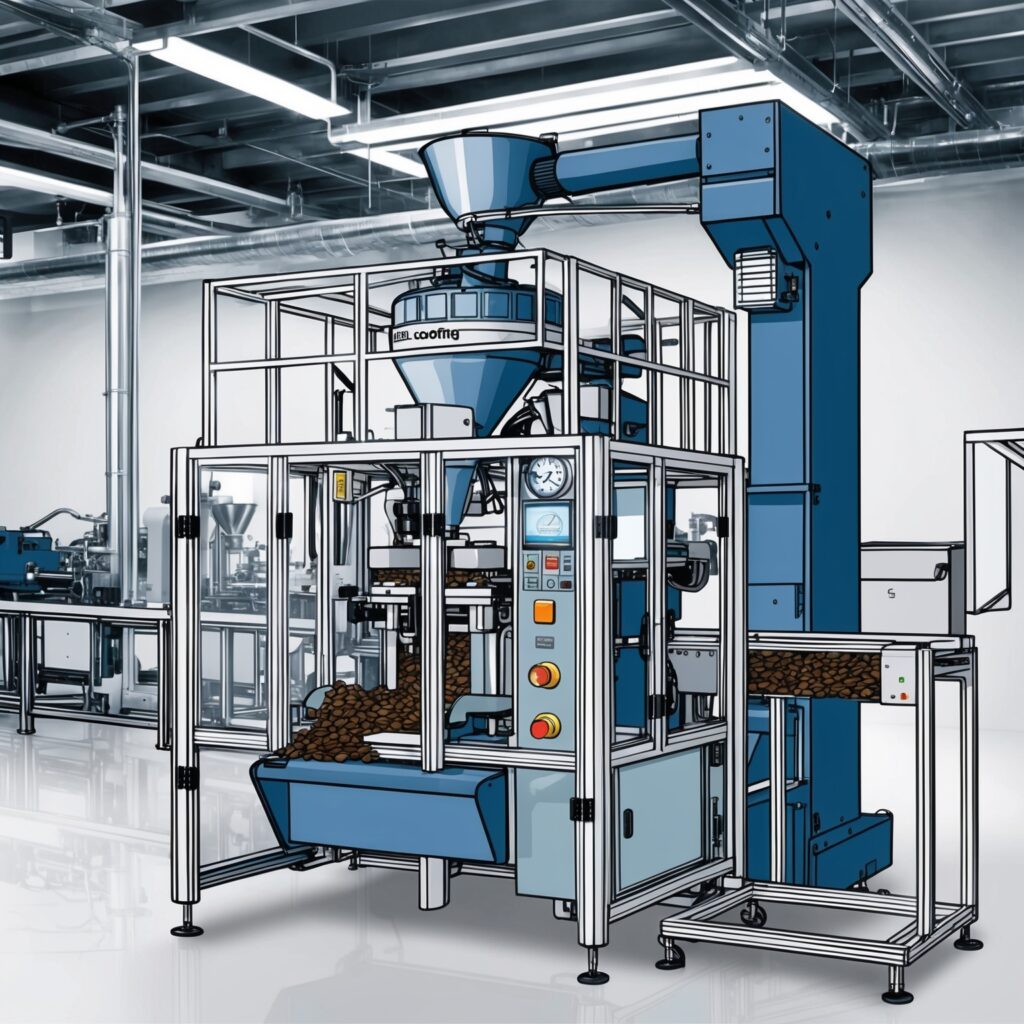

A VFFS, Vertical Form Fill Seal Machine, incorporates bag forming, filling products (granules, solids, powder, and liquids), sealing, and printing codes into one step, which has become an indispensable part of today’s packaging industries. The Vertical Form Fill Seal Machines Market Revenue was concluded at USD 2.5 Billion in 2024 and is estimated to achieve USD 4.2 billion by 2033 with a CAGR of 6.1% from 2026 to 2033. Many manufacturers currently use Vertical Automatic Packaging Machines in different industries to package various products, such as cosmetics, foods, beverages, pet foods, pharmaceuticals, personal care, agriculture, and even small toys. Besides VFFS’ wide applications and high production efficiency, their wide packaging formats also provide businesses with more space to create marketing content. Today, Many manufacturers currently use Vertical Automatic Packaging Machines, we will help you figure out what exactly VFFS stands for? How vertical packaging machines work? What crucial parts VFFS have and decide their quality? What the history of VFFS?, and the global market insights of VFFS.

How VFFS works?

The Vertical Form Fill Seal (VFFS) machine operates through a sophisticated, highly automatic, and synchronized sequence of procedures to transform a continuous roll of flexible packaging film into individual, product-filled, and sealed pouches/bags/sachets. The VFFS packaging process starts at the film unwinding and transportation. A roll of packaging film, which is installed at the rear of the auto packaging machine, would be precisely unwound and driven forward through a series of rollers and tensioning system, typically including a dancer arm. This procedure allows for a wrinkle-free and consistent supply of film, which decides effective bag forming and sealing. Some advanced vertical packaging machines utilize servo motors for highly accurate film indexing, allowing for precise control over bag length and printing graphics registration. Furthermore, it may pass through optional printers for additional functions, such as date codes, batch numbers, or other variable data. The printers could be thermal or ink-jet. Then, a vertical auto packaging machine comes to the most central part, BAG FORMING. The flat film is guided over a forming shoulder or collar, a precisely shaped funnel-like component that folds the film into a vertical tube. The dimensions of the forming shoulder dictate the width of the final bag. Once the film is formed into a tubular shape, its two outer edges would be brought together and sealed vertically by the vertical sealing system. The auto packaging machines typically involve heated sealing bars that have pressure and heat to fuse the inner layers of the film, creating a continuous back seal. Moreover, the operators could set VFFS machines to generate a lap seal where one edge overlaps the other or fin seal which the inner edges are sealed together. Currently, the lap seal is widely used by manufacturers since it creates a more flawless outlook and better sealing result. Even the width of final bag is predetermined by the forming shoulder, we are free to change the bag volume through adjusting the bag length.

With the continuous bag forming and vertically sealing, the next critical step is filling. The product would be dispensed through a filling system integrated at the top of the forming tube. However, the type of filling system varies depending on the product characteristics. For free-flowing granules or powders, volumetric cup fillers or multi-head weighers are commonly used to fill precise quantities. For powders, auger fillers with rotating screw mechanism generate accurate dosing. Liquids and viscous products are typically handled by piston pumps or gravity-fed systems. The filling process is precisely timed and synchronized with the intermittent movement of the film tube. Once the default amount of product filled, the horizontal sealing and cutting system takes over. A set of heated sealing jaws descends and seals across the filling tube, creating the top seal of one bag and the bottom seal of the next bag simultaneously. Later, a cutting part closed to the sealing jaws would cut and separate the completed, filled, and sealed bag from the tube. The cutting device could be a hot knife, a cold knife, or a tear-notching device which applies easy opening for users. Finally, the finished bags are discharged from the machine via a conveyor system, ready for further downstream processing such as carton packing or case packing.

The noteworthy thing is that VFFS machines employ a Programmable Logic Controller (PLC) and a Human Machine Interface (HMI) to fullfill the entire processes automatically, allowing operators to monitor, manage parameters (e.g., bag length, sealing temperature, and speed), and maintain the machine.

Major Components of VFFS

- Film Unwind and Transport System:This includes the film roll spindle, unwind rollers, a tensioning mechanism, and film transport belts driven by serve motors. This system ensures a consistent and controlled feed of the packaging material into the vertical packaging machine through holding, guiding, unwinding, and transporting the roll of packaging film.

- Bag Forming Tube: This core component transforms the flat packaging film into tubular structure which is prototype model of the final bag. The forming tube itself provides internal support for the film as it is being formed and filled. Different forming tube/shoulder could generate different bag styles (widths).

- Vertical Sealing Jaws: These components decide the quality and styles of backing seal. The vertical sealing mechanisms could be composed of heated jaws, crimpers, and rotary drum seals.

- Horizontal Sealing and Cutting: This working step impacts VFFS machines’ production speed since the precise cutting and sealing allow for a vertical packaging machine’s continuous motion without shutdown.

- Filling System: Vertical Form Fill Seal Machines could apply in filling liquids, powder, solids, or granules thanks to various filling components such like pumps, weigher, screw auger, and cups.

- Control System with PLC & HMI: The Programmable Logic Controller and Human Machine Interface working together generates the smart “ brain” of a automatic vertical packaging machine. Operators only need to set several parameters on a touchscreen with preferred language setting, the VFFS machine will automatically placing the film, forming the bag, filling products, and sealing.

- Strong Frame and Structure: The robust machine frame, typically made of stainless steel, provides a stable platform for all the components and ensures durability and hygiene, especially in food and pharmaceutical applications.

- Optional Components: Depending on the specific application, VFFS machines can add additional features such as printers, label applicators, nitrogen gas flushing systems for modified atmosphere packaging, punching device for packaging bulk coffee beans, dust extraction systems, and specialized bag style forming attachments for gusseted or stand-up pouches.

Continuous V.S. Intermittent VFFS

Vertical Form Fill Seal Machines have two types based on their motion methods and timing of sealing. Intermittent VFFS machines follow a stop-and-go working principle. The packaging film stops momentarily while the filling and sealing processes occur. However, Continuous VFFS machines operate with the packaging film constantly in motion throughout the entire packaging cycle.

Continuous VFFS | Intermittent VFFS |

| Higher Speed – 80 to 200 bags/min, making them ideal for high-volume production. | Lower Speed – Due to the stop-and-go motion, these machines generally have lower packaging speeds compared to continuous motion machines, generally 30 to 80 bags/min, upon bag size and product. |

| Better For Fragile Products – The continuous motion minimizes product agitation and dropping, making fragile items drop smoothly. Ideal for potato chips, snacks, candies, and baked goods. | Higher Accuracy – The stationary film during filling and sealing allows for more precise product placing and more stable sealing, making them suitable for products requiring accurate dosing. |

| Perfect for High-volume and Consistent Products – compared with the intermittent VFFS, the continuous VFFS provides a perfect packaging solution to the large scale production of relatively standard products. | Handling Versatile Products – Intermittent VFFS machines can handle more products, including powders, granules, liquids, and even larger or irregularly shaped products, since the stop motion offers more time for the product to settle. |

The Development History of VFFS

The history and development of Vertical Form Fill Seal Machines , VFFS, represent a significant evolution in packaging technology, driven by the increasing demand for efficient, cost-effective, and versatile packaging solutions across various industries. The genesis of the VFFS machine can be traced back to 1936 when Walter Zwoyer patented his innovative idea while working for the Henry Heide Candy Company. This innovation was a breakthrough, applying the concept of a machine that could do bag-making, product filling, and sealing the bag vertically from a roll of film on a continuous basis. This groundbreaking innovation targeted primarily the confectionary industry, demonstrating the potential of mechanized packaging. The greatest leap was with the incorporation of electronic controls and later Programmable Logic Controllers in the late 20th century. These enabled further accuracy, speed, and flexibility in machine operation. Operators could now easily set parameters like bag length, seal time, and fill volume using friendly interfaces.

Key Improvements Today VFFS

- Servo Motor Driven: Replacing traditional mechanical drives with servo motors offers enhanced accuracy in film transport and sealing, leading to higher production speed.

- Advanced Sealing Technologies: The show up of improved heat-sealing methods, ultrasonic sealing, and impulse sealing ensured stronger and more reliable sealing performance regardless of packaging film materials.

- Film Handling Systems: Innovations in film unwinding, tension control, and film tracking allowed for the use of complex packaging films, improving efficiency and package aesthetic.

- Diverse Bag Styles: Upgraded VFFS technology can produce a wide array of bag formats beyond the traditional pillow pouch, even gusseted bags, stand-up pouches, and shaped bags, catering to diverse marketing effects and consumer convenience demands.

- Sustainable Packaging Solutions: Recent packaging developments focus on how VFFS machines could handle sustainable packaging materials, such as recyclable, compostable, and biodegradable films, aligning with growing environmental concerns.

VFFS Packaging Film Materials

After learning about how vertical auto packaging machine works and what product VFFS can package, we should take a deep insight of the packaging film materials to help us understand whether a vertical form fill seal machine suits to your industry. The selection of the appropriate packaging film is critical for the ending results of a VFFS machine, the protection of the product, and the aesthetic appeal of the final package.

| Polyethylene (PE) | A widely used and cost-effective material, known as its excellent heat-sealing and moisture barrier characteristics. PE is often used for packaging snacks, frozen foods, and powders. |

| Polypropylene (PP) | Offers good clarity, stiffness, and a higher temperature resistance than PE. Especially, the BOPP films have enhanced strength and clarity, ideal for snack foods, confectionery, and baked goods. |

| Polyester (PET) | Known for high tensile strength, puncture resistance, and good temperature stability. PET films provide excellent barrier against moisture and oxygen, often used in packaging coffee, retort pouches, and liquids. |

| Aluminum Foil Laminates | These multi-layer structures incorporate a layer of aluminum foil to provide an absolute barrier against light, oxygen, moisture, and aroma. They are perfect for packaging sensitive products like coffee, pharmaceuticals, and high-barrier food applications. |

| Metallized Films | These films have a thin layer of metal, typically aluminum, onto a PET or BOPP. They provide reinforced barrier properties and a shiny, appealing appearance. They are commonly used for snacks, confectionery, and pet food packaging. |

Choosing an appropriate packaging film material should take careful consideration of several factors like the product’s nature: moisture content, oxygen sensitivity, texture, shelf life, package appearance, sealing results, and costs.

VFFS Market Size

The global demand for Vertical Form Fill Seal (VFFS) machines is experiencing robust growth, projected to reach substantial figures by the mid-2030. According to the Towards Packaging’s public study, the vertical form fill seal VFFS machines market size records USD 2.97 billion in 2025 and tend to increase to USD 5.32 billion by 2034. They also indicated that the huge growing demand in VFFS market came from e-commerce businesses. As the online shopping booms in most countries over the world, the manufacturing needs of flexible, protective and cost-effective packaging formats increase rapidly, particularly in China, India, and Japan. However, North America has the highest growth through growing demand for convenient ready-to-go foods, a strong base of manufacturing facilities, and expanding e-commerce together with increased relevance of sustainable packaging needs. The region of Europe already is a developed market with great focus on sustainability due to its heavy regulation, while Latin America, Middle East, and Africa present good opportunities for growth with expanding food and beverage consuming market as well as the growing pharma industries.

VFFS Machine Applications

Food & Beverage Vertical Packaging

Snack Foods Packaging Machines (Potato Chips, Corn Chips, Taro Chips, Biscuits, Crackers, Candies)

VFFS machines could gently and smooth handle the packaging of fragile items with high-speed as well as large production volumes, therefore prevent breakage and minimum production waste. Vertical Food Packaging Machine also has the ability to create various attractive bag styles (pillow, gusseted) for enhanced shelf appeal. They also ensure consistent fill weights and can incorporate gas flushing for extended shelf life.

Powders Food Packaging Solutions (Ground Coffee, Instant Coffee, Milk Tea Powder, Spices, Flour, Milk Powder)

VFFS provides accurate volumetric or auger filling, minimizing product waste. The sealed bags offer excellent protection against moisture and contaminants, maintaining product quality. Different bag formats like stick packs for single-serve portions are easily achievable.

Liquids Packaging Machines (Sauces, Juices, Salad Dressing, Soy Sauce, Dairy Products like Yogurt)

VFFS machines equipped with liquid filling systems like pumps offer a cost-effective way to package liquids in pouches with moderate speed, providing a convenient and often more sustainable alternative to rigid containers. They ensure leak-proof seals and can handle various pouch designs, including those with spouts. Compared with solely liquid filling machines, VFFS integrates bag forming within one machine for packaging liquid products.

Frozen Foods Packaging VFFS Machine (Vegetables, Meat, Fruits, French Fries, Hash Browns, Prepared Meals)

VFFS machines using specialized films suitable for low temperatures offer efficient and high-speed packaging of frozen goods. The strong seals maintain product quality and prevent freezer burn. Different bag sizes and formats can be accommodated, which make them suit to most consumption needs whatever restaurants, food supply chain, merchandising, or home use.

Cosmetics & Personal Care Automatic Packaging

Liquids and Creams Package (Body Lotions, Shampoos, Hair Conditioners, Body Wash)

VFFS offers flexible and aesthetically pleasing pouch/bag packaging for various liquid and viscous cosmetic products. It’s a cost-effective alternative to bottles and tubes, especially for samples and single-use applications. The soft and flexible packaging format also help save shipping space and secondary package costs, as well as easy storage.

Washing Liquid Packaging Machine (Laundry Liquids, Laundry Detergent, Fabric Conditioner, Liquid Soap, Hand Sanitizer)

Vertical Form Fill Seal Machines could provide cost-effective packaging solutions with high-speed output speed and variable packaging film materials to daily necessary washing liquids, also ensure strong sealing performance and better shipping formats.

Pharmaceuticals Packaging Solutions

Tablets and Capsules Package

VFFS machines offer hygienic and automated packaging, reducing the risk of contamination. They provide accurate counting and filling, ensuring correct dosages. Individual blister pack alternatives or sachet packaging for single doses are efficiently produced.

Powders and Granules Packaging Machine (Medications, Supplements)

VFFS ensures precise dosing through volumetric or gravimetric filling systems. The sealed sachets or pouches offer excellent barrier properties to protect sensitive medications from moisture and light, maintaining their efficacy.

Medical Devices (Syringes, Bandages, Test Strips)

VFFS machines can create sterile and tamper-evident packaging essential for medical devices. They can handle various shapes and sizes, ensuring product integrity and patient safety.

Agriculture Products Packaging

Seeds

VFFS machines offer accurate weighing and packaging of seeds in various quantities. The sealed bags protect seeds from moisture and pests, ensuring viability.

Fertilizers and Pesticides (Granular and Powdered)

VFFS provides efficient and secure packaging of agricultural chemicals, preventing leaks and ensuring safe handling. Robust film materials can be used for durability.

Animal Feed (Pellets, Crumbs)

VFFS enables high-volume packaging of animal feed in various bag sizes. Strong seals maintain freshness and prevent contamination.

Pet Food Vertical Form Fill Seal

Pet Food Packaging Solutions (Dry Kibble, Treats, Chews, Paste)

VFFS enables high-volume packaging of dry and semi-moist pet food. The robust seals ensure product freshness and prevent pest infestation. Features like resealable zippers can be easily integrated for consumer convenience.

SANEU VFFS Machine Guide

At SANEU, we understand you critical requirements for packaging various liquid, powdered, or granule products like ground coffee, fragile snacks, frozen foods, fabric softener, or viscous lotions. Our VFFS machines are designed to produce high-quality, leak-proof seals essential for whatever powdery, solid, or liquid containment, utilizing versatile durable and flexible packaging films. Whether your preference is for cost-effective pillow pouches, consumer-friendly pouches, or convenient sachets, SANEU offers tailored VFFS solutions to match your specific packaging format needs.

Since each product has its own specific packaging needs, that’s why our VFFS machines are designed for adaptability, allowing for quick and easy changeovers between different product types and package sizes. From ensuring the freshness of food products with gas flushing capabilities to providing sterile packaging for pharmaceuticals and creating attractive and functional pouches for cosmetics, SANEU offers comprehensive VFFS solutions. We are committed to providing high-quality machinery, expert technical support, and tailored configurations that empower your business to package a wide range of products with efficiency, reliability, and cost-effectiveness. Choose SANEU as your partner for all your vertical form fill seal packaging needs

Bag style

| Pros | Cons | ||

Pillow Bag | The most basic and common VFFS bag style. It’s formed by sealing the back edges together (fin seal), then top and bottom are sealed horizontally. | Cost-effective: Requires minimal film and is the simplest to produce. High-speed production: Well-suited for fast packaging lines. Versatile: Can be used for a wide range of products. Typical Products: Snacks (chips, crackers), confectionery (candies), powders, granules, small hardware items, pet food, frozen vegetables. | Limited shelf stability: Doesn’t stand upright on its own. Less premium appearance: Can look less sophisticated than other styles. |

Gusseted Bag | Similar to a pillow bag but with folded-in sides (gussets) that expand when the bag is filled. This creates a more three-dimensional shape and a flatter bottom, allowing it to stand more stably. | Improved shelf stability: Can stand upright more easily than a pillow bag. Larger fill volume: Gussets allow for more product to be packed in a smaller footprint. Better shelf presence: The expanded shape offers more surface area for branding and graphics. Typical Products: Coffee, tea, powders, grains, snacks, pet food, larger quantities of confectionery, some frozen foods. | More complex forming process: Requires additional forming components on the machine. Higher film usage: The gussets require more packaging material. |

Flat Bottom Bag | Features a flat bottom created by sealing and folding the bottom edges. This provides excellent stability, allowing the bag to stand upright very well. It often has vertical seals on the sides and a horizontal top seal. | Excellent shelf stability: Stands upright securely, maximizing shelf presence. Premium appearance: The flat bottom and clean lines give a high-quality look. Large printable surface area: Ideal for branding and product information. Consumer-friendly: Easy to store and pour from. Typical Products: Coffee, pet food, cereals, snacks, powders, detergents, premium food items. | More complex forming and sealing: Requires specialized tooling and more intricate machine movements. Lower production speed: Generally slower than pillow and gusseted bags. Higher machine cost: Machines capable of producing flat bottom bags are typically more expensive. |

Sachet (or Fin Seal Packet) | Small, flat pouches typically sealed on all four sides. They are often used for single-serve portions or samples. | Cost-effective for small portions: Minimal material usage. Convenient for single-use applications: Easy to carry and open. High-speed production: Can be produced very quickly. Small fill volume: Limited to single servings or small quantities. Typical Products: Sugar, salt, spices, coffee singles, powdered drinks, liquid samples (shampoo, lotion), pharmaceutical powders. | Limited branding space: Smaller surface area for graphics. Not stand-up: Lies flat and requires secondary packaging for display. |

Machine Parameter

SANEU offers a range of VFFS machines with different production capabilities, also could equip weighs, pump, screw augers for vertically sealing and filling most products on the market. The basic parameter distinguishing our VFFS machines is the film width, as this indicator get larger, the VFFS machine is capable of handling more products package needs.

VFFS 320 | VFFS 420 | VFFS 520 | VFFS 720 | VFFS 920 | |

|  |  |  |  | |

| Flim width | 120-320 mm | 420 mm | 520 mm | 720 mm | 920 mm |

| Bag length | 50-200mm | 80-300mm | 80-400mm | 80-500mm | 80-650mm |

| Bag width | 40-150mm | 50-200mm | 70-250mm | 60-350mm | 200-450mm |

SANEU Customers VFFS Cases

Here are three case studies highlighting SANEU customers in the Middle East, Europe, and Vietnam utilizing VFFS machines, Let’s take a look at how they are benefited from investing in SANEU vertical form auto packaging machines.

Case #1: Coffee Roaster From Saudi – Bulk Coffee Bean Packaging Solution

SANEU’s customer, a Coffee Roasters in Riyadh, is a prominent supplier of high-quality bulk coffee beans throughout the Saudi Region . The company was in trouble of finding a robust and efficient packaging solution to handle various quantities of whole and ground coffee beans, ensuring freshness and appealing to both retail and wholesale clients. Their previous manual and semi-auto packaging process was slow, labor-intensive, and lacked consistency in bag quality. They needed a solution which is capable of handling larger fill volumes while maintaining product freshness and offering a professional presentation. SANEU VFFS machine specifically designed for larger pouch formats and equipped with a expert filling system for accurate dispensing of bulk coffee beans. The machine also featured a gas flushing system to remove oxygen and extend the shelf life and aroma of the coffee. Especially, SANEU Vertical Form Fill Seal Coffee Packaging Machine has a unique technique of One-way Degassing valve applicator, doubly ensuring the packaged coffee avoiding oxygen and moisture as well as releasing CO2.

Case #2: Snacks Producer in Europe – Variety Snack Packaging

Our customer is a successful European manufacturer of a diverse range of popular snack foods, including potato chips, snacks, and confectionery items. They needed a flexible and high-speed packaging solution to handle their varied product line and different bag sizes, minimizing the production waster in the larger extend. They required a machine that could efficiently package different snack types with varying textures and densities while maintaining product integrity and offering attractive packaging for competitive retail environments.

SANEU chose a versatile continuous motion VFFS machine equipped with a multi-head weigher for accurate and high-speed filling of their diverse snack products. The machine was also designed for quick changeovers to accommodate different bag sizes and film types, allowing them to package their entire product range on a single system.

Case #3: VietClean Home Products- Washing Liquid and Conditioner Packaging

VietClean Home Products is a growing manufacturer of household cleaning consumption in Vietnam, specializing in washing liquids and fabric conditioners having exclusive fragrance. They sought an efficient and cost-effective way to package their liquid products in convenient and consumer-friendly pouches but highly sealed the liquids to ensure the aroma. SANEU suggested VietClean Home Products invested in a SANEU intermittent motion VFFS machine equipped with a liquid filling system featuring piston pumps for accurate dispensing of both washing liquid and fabric conditioner.

Review

VFFS machines have revolutionized packaging by automating bag forming, filling, and sealing in one vertical process, boosting speed and consistency. Their user-friendly automation, thanks to touchscreens and PLCs, simplifies operation. VFFS machines reduce labor and material waste, offering cost savings, and create professional packaging that enhances brand appeal. Ongoing innovation focuses on speed, flexibility, sustainability, and smart technology, ensuring VFFS machines remain essential for efficient packaging across industries.